Cleaning

Before cleaning, remove all external parts from the cylinder block and sensors. On HCS and Endura-E engines, check that the tappets and camshaft are removed from the engine. On CVH and PTE engines, remove the crankcase ventilation head located at the rear of the cylinder block and remove the crankshaft speed sensor from the front of the cylinder head. On Zetec and Zetec-E engines, unscrew the piston cooling oil nozzle and remove the oil passage plugs (see fig. 4D.63, 4D.64).

Remove all oil plugs from the engine. To remove the plug, drill a small hole in it, screw in a self-tapping screw and remove the plug by the screw. When assembling the engine, it is necessary to install new oil plugs. If the oil passages or cavities are heavily soiled, clean them with steam. Rinse all internal channels and cavities with warm water until water comes out clean. Then dry the cavities. Compressed air can be used to speed up the drying process. Apply a light coat of engine oil to cleaned and dried surfaces. If the cylinder block is not heavily soiled, it can be cleaned using a solution of hot soapy water and a stiff brush. Clean all threaded holes with an appropriate tap (see fig. 40.66).

After cleaning the cylinder block, install new oil line plugs.

On Zetec and Zetec-E engines, install new oil jets on the piston crowns.

Examination

Visually inspect the cylinder block for cracks and corrosion Check the diameter of each cylinder for wear.

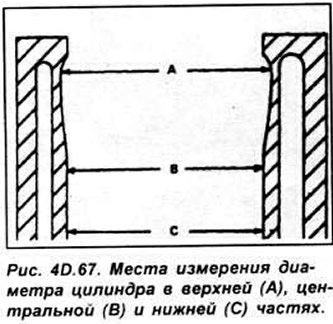

Measure the diameter of each cylinder at the top center and bottom, parallel to the axis of the crankshaft. Then measure the diameter of each cylinder in the same places perpendicular to the axis of the crankshaft (see fig. 4D.67).

Measure the piston diameter at the bottom perpendicular to the axis of the piston pin (see fig. 4D.68).

To determine the clearance between the piston and the cylinder, subtract the piston diameter from the cylinder diameter. You can also determine the gap using a feeler gauge when installing the piston in the cylinder. Take measurements on the remaining cylinders and pistons. Worn pistons must be replaced. On some engines, pistons are replaced only complete with connecting rods. If at least one of the cylinder diameters exceeds the allowable limits, then the cylinders must be bored and oversized pistons used.

If the cylinder and piston dimensions are correct, then only the piston rings may need to be replaced.

Visitor comments