Examination

When checking, the cylinder block and crankshaft must be clean. Turn the engine over with the crankshaft up.

Unscrew bolts of fastening of covers of radical bearings and remove covers. Arrange the covers in the correct order.

Remove the main bearings from the cylinder block and bearing caps. Wipe the bearings thoroughly.

Checking the clearance of the main bearings

HCS and Endura-E engines

Wipe the outer parts of the liners and their places of installation in the cylinder block and in the covers. Insert without lubrication (dry) upper liners in the cylinder block. Please note that the top liners are grooved. Check that the tab on each liner fits into the groove in the cylinder block.

Install the crankshaft half-ring into the cylinder block with the lubrication grooves facing away from the cylinder block (see fig. 4D.71).

CVH and PTE engines

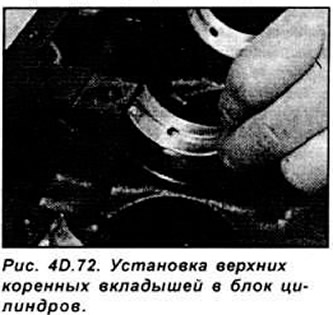

Wipe the outer surface of the main bearings and insert the upper bearings into the cylinder block. Note that with the exception of the front liner, the top liner is grooved. Check that the tab on each liner is seated in the groove in the cylinder block (see fig. 4D.72).

Install the crankcase breather head and retaining spring into position in the cylinder block (see fig. 4D.73).

Reinstall the crankshaft half rings with their oil grooves facing away from the engine block.

Zetec and Zetec-E engines.

Wipe the outer parts of the main bearings and install them in the cylinder block. Install the half shaft rings on the center bearing. Check that the tab on each liner fits into the cutout in the cylinder block (see fig. 4D.74).

All engines

Thoroughly clean the working surfaces of the liners and the crankshaft journal. Position a piece of Plastigage dipstick along each crankshaft journal (see fig. 40.75).

Clean the running surfaces of the lower main bearings and install them on the crankshaft. Install the main bearing caps. Do not move the measuring rods while doing this.

Screw in the required moment bolts of fastening of covers of radical bearings. Do not rotate the crankshaft while measuring the main bearing clearances.

Unscrew bolts of fastening of radical covers of bearings and remove them.

Measure the width of the Plastigage dipstick with a scale bar that indicates the size of the gap in each main bearing (see fig. 4D.76).

Thoroughly clean all traces of the measuring rod from the crankshaft journals and main bearings.

Installing the crankshaft

Remove the crankshaft from the cylinder block. Clean the running surfaces of the main bearings and lubricate them with a light coat of engine oil. Also lubricate the running surface of the crankshaft half shaft ring.

Lubricate the crankshaft journals in contact with the oil seal.

Install the crankshaft to the cylinder block. Clean the running surfaces of the lower main bearings, then lubricate them with a thin layer of engine oil and install on the crankshaft. Install the main bearing caps according to the identification marks. The arrows on the main bearing caps must be directed towards the drive of the gas distribution system (see fig. 4D.77).

Gradually and evenly from the center to the edge, tighten the bolts securing the main bearing caps to the required torque.

Turn the crankshaft by hand. The crankshaft should rotate easily and evenly.

Check crankshaft end play. Install the left crankshaft oil seal cover.

Visitor comments