Withdrawal

Remove the negative terminal from the battery. Remove the air filter.

Thoroughly clean all external dirt from the carburetor, disconnect the fuel supply and return hoses from the carburetor, after marking them. Close the ends of the hoses with plugs. Disconnect the wires from the anti-knock solenoid valve. Remove the choke control cable. Unscrew 6 fixing screws (4 of which are TORX type) and, being careful, lift the top cover of the carburetor. Turn the carb cap over to access the float and remove the float pin from the top carb cap, tapping gently if necessary. Remove the float (see fig. 4A.23, 4A.24).

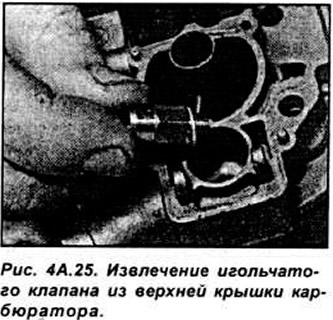

Unscrew the needle valve body and remove it from the top cover of the carburetor. Remove the needle valve gasket from the carburetor top cap (see Figure 4A.25).

Check components for damage and replace if necessary. Check the needle valve for wear and the float for leaks. Clean the float chamber.

Install a new gasket on the needle valve and, being careful, screw it into the cap.

When installing the float and needle valve, make sure the float lug is located under the spring clip on the needle valve. Install the float pin in place.

Check and, if necessary, adjust the float level.

After making sure that the mating surfaces of the carburetor and carburetor cover are clean, install a new gasket on the carburetor body and on top of the carburetor cover.

Connect the fuel hoses and the anti-knock valve electrical connector and choke cable. If any of the hoses were originally secured with twist-on clamps, remove them and replace with standard hose clamps.

Install the air filter.

Connect the negative terminal to the battery, start the engine and check the quality of the mixture and idle speed.

Float level adjustment

Install a new gasket on the carburetor cover, then install the cover vertically. In this case, the needle valve is located in the extreme upper position and is closed.

Measure the distance between the top cover gaskets and the bottom of the float (see fig. 4A.26).

If the distance does not correspond to the required one, then adjust it by bending the protrusion on the float assembly.

Visitor comments