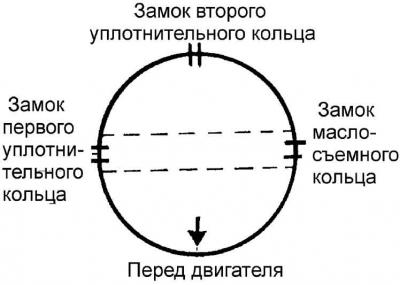

Mutual position of piston ring locks

The service life of the engine without cylinder boring can be significantly increased by installing a special oil scraper piston ring.

1. Remove the top o-ring, middle o-ring and oil scraper ring in turn. To remove the rings, insert thin steel plates under the ring (can probes) in several places evenly along the perimeter of the piston and along the plates, slide the piston ring off the piston.

2. Check the gap in the ring lock. To do this, sequentially insert all the rings from the upper side into the working cylinder sleeve.

3. With the piston upside down, push the ring down into the cylinder to a depth of 15 mm and measure the gap in the ring lock with a feeler gauge. The gaps in the lock of the ring are not adjustable, therefore, if the gap increases beyond the allowable one, the ring must be replaced.

4. To determine the clearance of the pistons in the cylinders, measure the diameter of the cylinders. Cylinders are measured in the longitudinal and transverse direction at three levels along the height of the cylinder. Then subtract the piston diameters from the cylinder diameters to obtain the piston clearance in the cylinder. If the clearance is out of tolerance, new sets of pistons and cylinder liners should be installed.

5. Install piston rings on piston.

6. Check the gap in the groove between the piston and the piston ring, lubricate the rings with oil and turn on the piston so as to obtain the correct relative position of the locks.

Visitor comments