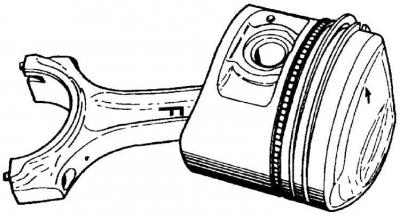

Mutual position of piston ring locks

Withdrawal

1. Remove cylinder head and oil sump.

2. Check the numbers on the connecting rod caps and connecting rods and their position. Connecting rod No. 1 is located on the drive side of the gas distribution system.

3. If there is carbon deposits on the top of the cylinder, remove it using a soft scraper.

4. Turn the crankshaft by the pulley bolt until the piston of the first cylinder is in the BDC position. Unscrew the connecting rod cap and remove it together with the connecting rod bearing.

5. Remove the piston with the connecting rod up.

6. Remove the rest of the pistons in the same way.

Check and repair

1. Remove the top o-ring, middle o-ring and oil scraper ring in turn. To remove the rings, insert thin steel plates under the ring (can probes) in several places evenly along the perimeter of the piston and along the plates, slide the piston ring off the piston.

2. Check the gap in the ring lock. To do this, sequentially insert all the rings from the upper side into the working cylinder sleeve. With the piston upside down, push the ring down into the cylinder to a depth of 15 mm and measure the gap in the ring lock with a feeler gauge. The gaps in the lock of the ring are not adjustable, and if the gap increases beyond the allowable one, the ring must be replaced.

3. To determine the clearance of the pistons in the cylinders, measure the diameter of the cylinders. Cylinders are measured in the longitudinal and transverse direction at three levels along the height of the cylinder. Then subtract the piston diameters from the cylinder diameters to obtain the piston clearance in the cylinder. If the clearance is out of tolerance, new sets of pistons and cylinder liners should be installed.

4. Install piston rings on piston. The surface of the top O-rings is coated with a thin layer of molybdenum, so care must be taken when installing the rings on the piston to avoid damaging this layer. The oil scraper ring is installed in such a way that the manufacturer's mark is directed to the piston head or the recess to the piston pin.

5. Check the gap in the groove between the piston and the piston ring, lubricate the rings with oil and turn on the piston so as to obtain the correct relative position of the locks (see fig. Mutual position of piston ring locks).

Installation

Attention! Always replace the 4-piston set with the pins. If it is necessary to grind one cylinder, grind everything and replace all pistons together with the fingers. The same diameter also means that they have the same mass, which in turn is a condition for proper engine balancing.

1. Compress the piston rings with a mandrel.

2. Insert the piston with the connecting rod into the cylinder, with the arrow on the bottom of the piston pointing towards the timing gear.

3. Install the connecting rod cap and tighten the bolts to the specified torque.

4. Install the oil sump and cylinder head.

5. Fill the engine with engine oil and coolant into the cooling system.

Visitor comments