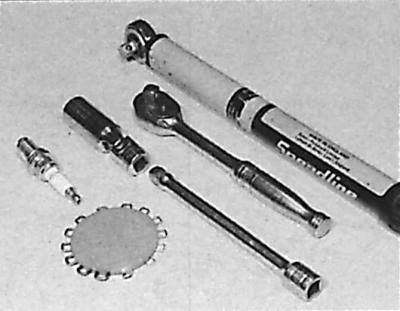

Tools needed to unscrew the spark plug and adjust the electrode gap

Proper functioning of spark plugs is one of the most important conditions for the efficient operation of the engine. It is essential that only the specified type of spark plugs be fitted to the engine. With a good engine, cleaning spark plugs is a rare operation.

1. Mark the location of the high voltage wires on the spark plugs.

2. Remove the high voltage wire ends from the spark plugs by pulling on the end, not on the wire.

3. Using a spark plug wrench, unscrew the spark plugs from the engine. Beforehand, using a vacuum cleaner or a jet of compressed air, it is necessary to clean the space near the candles from dust and dirt so that it does not get into the engine cylinders.

4. Visual inspection of the working part of the spark plugs can show the condition of the engine. If the nose of the spark plug insulator is clean and white with no deposits, then the mixture is too lean. It also indicates that the spark plug is too hot, i.e. heat is slowly removed from the center electrode. If this is the case, then it is necessary to adjust the composition of the fuel mixture or replace the spark plug.

5. If the nose of the insulator is covered with a black coating, then this indicates that the mixture is too rich. If the plaque is black and oily, then this indicates engine wear and the need to check and repair it.

6. If the nose of the insulator is covered with a light brown coating, then the mixture is optimal and the engine is in good condition.

7. The gap between the electrodes of a spark plug is of great importance, since too large and too small a gap changes the size of the spark, which leads to a decrease in engine efficiency. The gap must always comply with the technical requirements.

|  |

8. Gap check is carried out with a wire gauge (left) or probe (on right).

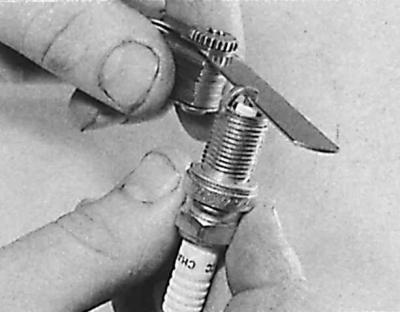

9. The gap is adjusted by bending the side electrode. In no case should the central electrode be bent, as this can lead to breakage of the insulator and failure of the candle.

10. To bend the side electrode of the candle, you must use a special tool.

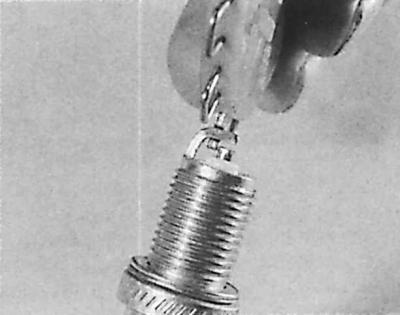

11. Before installing the spark plug in the engine, check that the threads are clean and that all threads are intact.

12. Screw in the spark plugs by hand and then tighten them to the required torque. If a torque wrench is not available, tighten the spark plugs until you feel resistance, then tighten 1/16 turn on OHV engines or 1/4 turn on CVH engines.

13. Connect high voltage wires to spark plugs.

Visitor comments