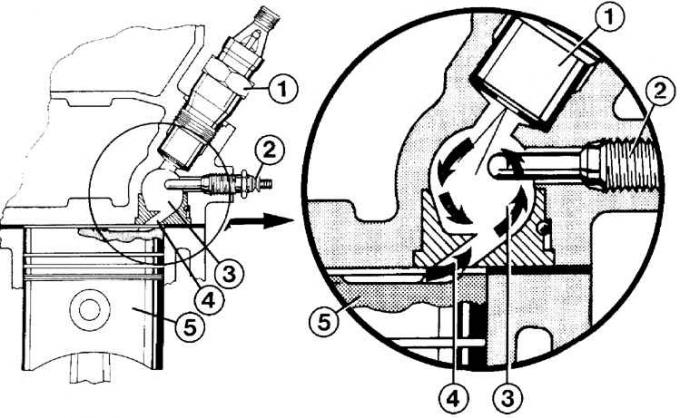

Vortex chamber

1 - nozzle; 2 - glow plug; 3 - vortex chamber; 4 - channel; 5 - piston

When the diesel engine is running, fresh air, having passed through the filter, is sucked into the cylinders and compressed strongly, as a result of which it is heated to a high temperature. When the piston approaches top dead center on the compression stroke, diesel fuel is injected into the compressed and heated air and self-ignites.

To facilitate the start of a cold engine, two autonomous systems are used. One of the systems during cold start-up maintains increased idle speed until the engine warms up.

The second system serves to improve the ignition of the fuel in the cylinders at the time of start. Glow plugs are installed in the swirl chambers of each cylinder. Before starting the engine, they are energized, which indicates the ignition of the control light on the instrument cluster. Within a few seconds, the candles heat up to a high temperature and the control lamp goes out, which serves as a signal to start the engine. Hot plugs raise the temperature in the swirl chamber and make it easier to ignite the fuel. It should be noted that the candles do not turn off immediately after starting the engine, but after some time, allowing the engine to enter normal operating mode. The failure of even one candle leads to difficult starting of the engine with interruptions in operation and strong vibration.

The fuel system is designed to clean and supply atomized fuel to the engine cylinders in the amount necessary for the corresponding mode of operation.

The fuel system includes a rear-mounted fuel tank, fuel filter, high pressure fuel pump, injectors, high and low pressure fuel lines.

The booster pump draws fuel from the tank and directs it to the filter. The filter retains mechanical impurities and water contained in the fuel. A manual fuel pump is mounted in the fuel pump housing. After being cleaned in the filter, the fuel enters the high pressure fuel pump.

The amount of fuel supplied to the cylinders is regulated by a dispenser controlled by a cable from the accelerator pedal. The injection advance angle is changed depending on the engine speed by a mechanical centrifugal regulator built into the injection pump.

The high pressure fuel pump is maintenance free. The fuel pump is driven from the crankshaft on an engine with a displacement of 1.6 dm3 through three spur gears or on an engine with a displacement of 1.8 dm3 - through an additional gear belt.

There is a solenoid valve to stop the engine. When the engine is started, a voltage of 12 V is applied to the valve winding, the valve opens and passes fuel to the pump and injectors. When the engine is turned off by turning the key in the ignition switch, the fuel valve is turned off and the fuel supply is cut off.

A high-pressure fuel pump supplies fuel through pipelines to the injectors that are installed in the cylinder head near the combustion chambers. The injectors inject fuel into swirl chambers where the fuel is ignited.

Injectors are a valve that opens at a strictly defined fuel pressure (110–120 bar). The atomizer, located at the lower end of the nozzle, forms a torch of sprayed fuel of the required shape. The fuel is cut off by a needle under the influence of the nozzle spring. The atomizer and needle are a precision assembly and must be handled with care when repairing. Excess fuel after cut-off seeps along the needle, lubricating it, and is discharged through the return pipeline to the tank.

Serviceability and correct adjustment of injectors are very important for the normal operation of the engine. If the nozzle atomizer does not provide the desired shape of the flame or a bad cutoff occurs, the engine starts to work with vibration, strong mechanical knocks appear, and smoke increases.

Attention! The injection pressure is an adjustable parameter. During engine operation, the injection pressure often drops, so the nozzle must be checked periodically and, if necessary, adjusted.

It should be noted that nozzles from different engine models are externally the same, but have different characteristics, in particular, the shape of the torch, so only those new nozzles that are designed for this model should be used.

Since November 1987, the 1.6 dm3 engine has been equipped with an exhaust gas recirculation system. Part of the exhaust gases, while appearing in the engine cylinders and burned. The valve system ensures the correct dosing of recirculated gases. The temperature sensor, located on the thermostat housing of the cooling system, interrupts the operation of the system when the engine temperature is below 60°C. The exhaust gas recirculation system is maintenance-free. Only after the high pressure fuel pump has been removed can the vacuum control valve be checked and, if necessary, adjusted.

Visitor comments