Disassembly

1. Remove intake and exhaust manifolds.

2. Unscrew the two brackets with holes for lifting the engine and the oil pressure sensor from the cylinder head.

3. Remove the vacuum pump by unscrewing in series (and at the same angle) two mounting bolts.

4. Remove bearing caps #2 and #4 of the camshaft.

5. Unscrew the nuts of the remaining camshaft bearing caps 1/4 turn.

6. Remove the camshaft bearing caps together with the upper shells and seals and remove the camshaft.

7. Remove the tappets together with the valve clearance adjustment plates and position them so that they can be installed in the same seats in the cylinder head when they are assembled.

8. Remove the vacuum pump drive.

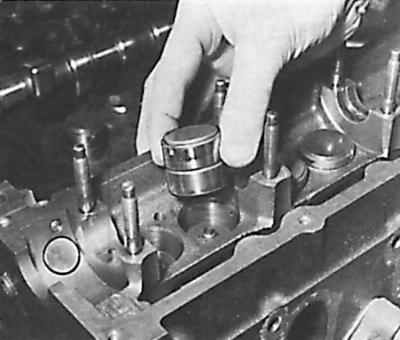

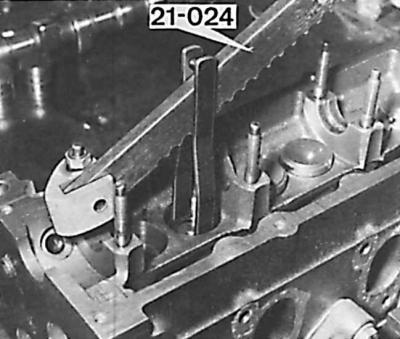

9. With the aid of a device (21.024) compress the individual valve springs and remove the crackers.

10. Remove the tool and remove the upper spring plates, springs and valves.

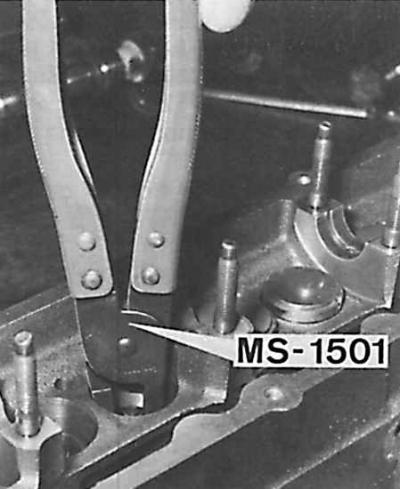

11. With special forceps (MS-1501) remove the oil seals from the valve stems.

Examination

After disassembling the cylinder head, thoroughly wash all parts, check their technical condition and evaluate their suitability for further work. All gaskets should be replaced and the valves should be lapped.

Assembly

1. Lubricate the valve stems with engine oil and insert them into the guides.

2. Wrap the ends of the valve stems with adhesive tape so that they do not damage the sealing edges of the caps, and use special tool 21.007 to fit the caps onto the valve stems.

3. Install the valve springs and upper plates and use special tool 21.024 to compress the springs and insert the cotters.

4. Lubricate the vacuum pump drive rod with engine oil and insert it into the hole in the cylinder head.

5. Lubricate the tappets with oil and install them, together with the valve lash adjusting plates, into the seats in the cylinder head in which they were previously installed.

6. Insert the lower camshaft bearing shells into the sockets in the cylinder head and lubricate them with engine oil.

7. Install the camshaft on the liners; the eccentric at the end of the shaft must point upwards.

8. Install the upper bearing shells in the camshaft bearing caps and lubricate them with oil.

9. Place washers under the cylinder head so that the valves can move in the guides.

10. Apply sealing paste SPM-4G911 ZF/G to the sealing surface of bearing No. 1 of the camshaft (from the drive side of the gas distribution system).

11. Install the camshaft bearing caps No. 1, 3 and 5. Designations on them (arrows) should be directed forward (towards the drive of the gas distribution system).

12. Tighten the camshaft bearing cap nuts by hand.

13. Tighten the camshaft bearing cap nuts #3, then #1, then #2 with a 180°wrench.

14. Repeat the last operation until the covers are exactly in place.

15. Install bearing caps #2 and 4 with plastic hammer blows.

16. Tighten all camshaft bearing cap bolts to the correct torque.

17. Lubricate the camshaft sealing ring with engine oil and insert it with special tool 21.110.

18. Fit the vacuum pump together with the O-ring and tighten its fixing bolts sequentially and evenly to the correct torque.

19. Screw two brackets with holes for engine lifting to the cylinder head and screw in the oil pressure sensor.

20. Screw the exhaust and intake manifolds together with new gaskets to the cylinder head and tighten the bolts and nuts of their fastening to the appropriate torque.

Visitor comments