Insert the main bearing shells. Lubricate the main and connecting rod journals of the shaft and the liners of the main bearings with oil.

Install the crankshaft on the main bearing shells in the engine block. Install the main bearing caps (arrows on the covers directed towards the drive of the gas distribution system) along with inserts. Lubricate the threads of the new main bearing cap bolts with oil. Tighten the main bearing cap bolts to the correct torque.

If the piston rings were removed, then install them on the pistons with the inscription "TOR". directed towards the bottom of the piston. Position the locks of the rings at an angle of 120°.

Lubricate the smooth surface of the cylinders, the side of the pistons and the piston rings with oil. Install the half shells in the connecting rod bases.

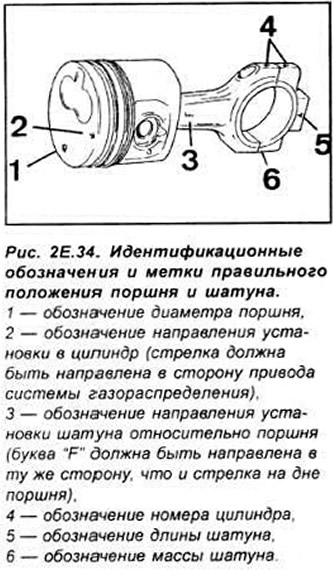

Install the piston-rod units in the cylinders, paying attention to the installation marks (see fig. 2E.34):

- connecting rod and cap are marked with the number of the cylinder in which they are installed (cylinder No. 1 from the drive side of the gas distribution system).

- arrow on the bottom of the piston and the letter "F" on the side surface of the neck of the connecting rod should be directed towards the drive of the gas distribution system.

- connecting rods are divided into four selection groups differing in the distance between the axes of the holes of the head and the base, this allows you to limit to a minimum the difference in the protrusion of the piston above the upper plane of the cylinder block (and thus the difference in compression ratio in the individual cylinders), the selection group of the distance between the axes of the connecting rods is indicated by the letters "A "IN ". "WITH" and about" embossed on the connecting rod caps (letter "A" belongs to the shortest connecting rods).

- connecting rods are divided into two selection groups depending on their mass "light" (easy) And "heavy" (heavy), all connecting rods in the engine must belong to the same mass group.

Insert the half shells into the connecting rod caps.

Lubricate the connecting rod bearings and shaft journals with oil. Install the connecting rod caps, paying attention to their designation (see fig. 2E.34).

Insert new connecting rod cap bolts and lubricate their threads with oil.

Tighten the connecting rod cap bolts to the correct torque. Lubricate the O-ring of the oil supply pipe to the oil pump with oil. Install the oil supply line and check that the gasket is in the correct location. Install the crankshaft rear cover with a new gasket that reaches the bottom of the engine block. Tighten the rear cover mounting bolts.

Install with tool 21.148 and the mounting bolt the crankshaft pulley, the front plate of the cylinder block together with a new gasket.

Lubricate the front crankshaft journal and the pulley O-ring with oil.

Install the pulley on the crankshaft, making sure that the keyway with the key in the neck is exactly opposite the groove in the pulley.

Lubricate the intermediate shaft and bearing bushes in the cylinder block, as well as the front support plate with oil.

Establish in the block of cylinders an intermediate shaft together with a basic plate.

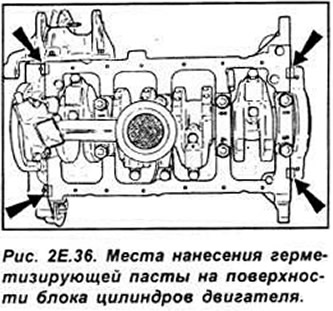

Lubricate the indicated places (see fig. 2E.36) a thin layer of sealing paste and install the oil pan with a new gasket. First insert the four mounting bolts at the corners of the oil pan, tighten them by hand, then insert and tighten the rest of the oil pan mounting bolts by hand. Tighten the bolts - with the exception of the bolts in the corners of the pallet - to the appropriate torque. Tighten the bolts at the corners of the oil pan to the correct torque. Install the water pump with a new gasket. Fill the oil pump with about 10 cm3 of oil Install the oil pump. Screw on the oil filter. Install the engine cylinder head.

Install the generator. Install the fuel pump. Install the pulley on the crankshaft. Install the flywheel on the crankshaft.

Install the clutch on the flywheel. Install the starter Install the exhaust manifold.

Visitor comments