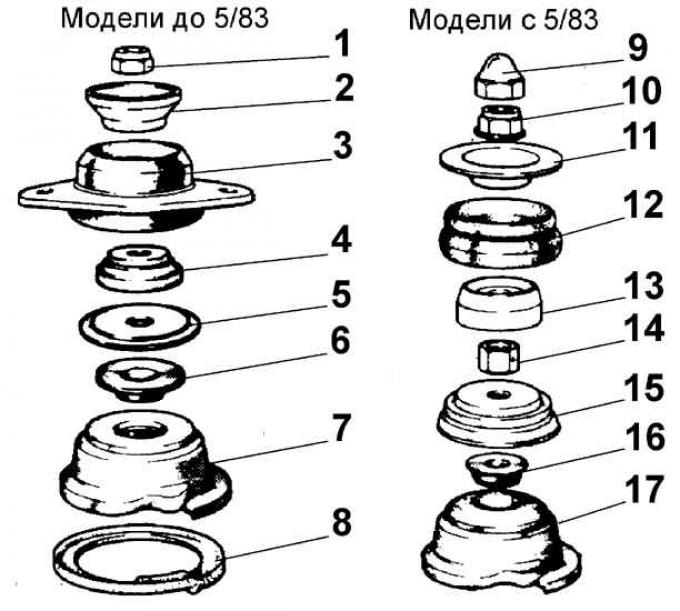

Details of the upper part of the suspension strut

1 - top nut; 2 - conical washer; 3 - support bearing holder; 4 - intermediate sleeve; 5 - pressure washer; 6 - support bearing; 7 - the upper plate of the spring; 8 - thrust buffer; 9 - protective cap; 10 - top nut; 11 - conical washer; 12 - support; 13 - centering ring; 14 - lower fastening nut; 15 - pressure washer; 16 - support bearing; 17 - upper spring plate

Withdrawal

1. Remove shock absorber.

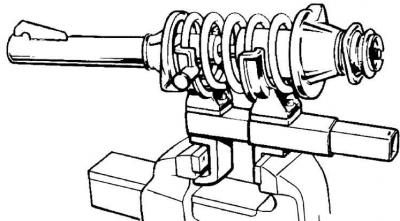

2. Install the spring compressor on the vise, insert the rack spring into it and slowly compress the spring until the spring load is removed from the top cup of the rack.

3. Unscrew the nut securing the upper suspension strut bearing. In cars of different years of manufacture, this operation is performed in different ways. When unscrewing the nut, keep the shock absorber rod from turning.

Vehicles up to 05.1983

4. Unscrew the nut securing the upper shock absorber support bearing and remove the support bearing, the upper spring cup and the spring in sequence.

Cars since 05.1983

5. Remove the washer, thrust bearing, centering ring from the shock absorber rod, unscrew the fastening nut and remove the upper spring cup, thrust buffer and spring.

6. Remove shock absorber from spring.

7. When replacing the spring, slowly open the tool and release the spring.

Installation

1. Check shock absorber before installation.

2. If a new spring is installed, compress it.

3. Install the shock absorber in the spring, making sure that the spring fits correctly on the shock absorber support cup.

4. Install the removed parts on the stem in the reverse order of removal.

5. While holding the stem from turning, screw on the nut.

6. Slowly unload the spring, while ensuring the exact position of the ends of the spring in the recesses of the spring cups.

7. Install the suspension strut on the vehicle.

Shock absorber check

Accurate check of parameters of the shock-absorber is made on a test bench. Approximately the state of the shock absorber can be determined by manually compressing or stretching the shock absorber removed from the car. In a working shock absorber, the rod should move evenly, with the same force from lock to lock.

Signs of a failing shock absorber

A failed shock absorber is determined by the following features:

- strong prolonged vibrations or buildup of the car body when driving on uneven roads;

- bouncing of the wheels and the appearance of vibration of the car body even on a flat road;

- deterioration of stability and skidding of the car when cornering.

Visitor comments