Withdrawal

The process of removing the cylinder head together with the manifolds is given.

On engines with a fuel injection system, depressurize the fuel system.

Remove the ground wire from the battery.

Remove the cylinder head cover.

On engines with a fuel injection system, remove the air supply pipes from the throttle body and air filter.

Drain the coolant from the cooling system.

Disconnect the hoses from the thermostat housing.

Disconnect the heater coolant hoses from the exhaust manifold and CFI unit.

Disconnect the accelerator cable from the throttle body.

Disconnect wires from radiator fan temperature sensor, coolant temperature sensor (under the intake manifold), and a control valve on the carburetor.

Disconnect the remaining multi-pin wiring connectors from the sensors in the intake manifold and from the oxygen sensor in the exhaust manifold or exhaust pipe.

On Endura-E engines, disconnect the wiring clamps and remove the four fuel injector multi-pin connectors.

On vehicles equipped with an air distribution system, remove the air duct and air filter.

Raise the front of the car and secure it on stands.

Unscrew nuts and bolts, and disconnect a receiving exhaust pipe from a collector. Remove the flange seal. Tie up the exhaust pipe with a soft wire to the body and lower the car.

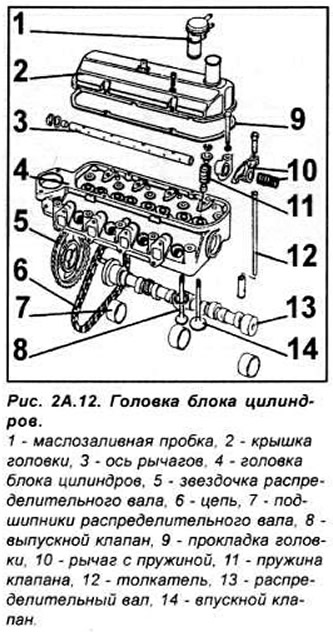

Unscrew four bolts of fastening, and remove the valve mechanism from a head of the block of cylinders. Raise pushers. Arrange them in assembly order, labeled 1 through 8.

Gradually and sequentially unscrew the head mounting bolts in the reverse order of screwing. After loosening all the bolts, remove the bolts, then lift the cylinder head and remove the gasket. Only a new gasket should be used. Head bolts can only be used twice, if it is not known how many times the bolts have been used, they must be replaced.

Preparing the head for installation

The mating surfaces of the head and cylinder block must be perfectly clean. Use a hard plastic or wooden scraper to clean them. Be careful when cleaning as aluminum alloy is very easy to damage. Check that carbon deposits have not entered the oil and water channels, this is especially important for the lubrication system, since carbon deposits can block the oil supply to engine components. Clean channels if necessary.

Check the mating surfaces of the cylinder head and block for nicks, deep scratches or other damage. If the defects are small, they can be removed by machining, but with significant defects, the parts must be replaced.

Using a metal ruler and feeler gauge, check the flatness of the mating surfaces.

Clean the bolt holes in the block. Screwing a bolt into an oil-filled hole can rupture the block due to hydraulic pressure.

Installation

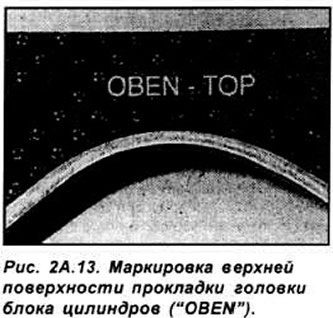

Check that the new cylinder head gasket is the same type as the original and that the marking "TOR" (or "OBEN") directed upward. Position the new cylinder head gasket on the surface of the cylinder block on the guide pins. Check that the holes are correctly aligned with the channels of the cooling and lubrication system (see Figure 2A.13).

Install the head to the cylinder block. then insert the bolts and tighten them by hand.

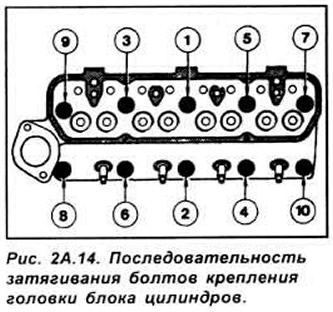

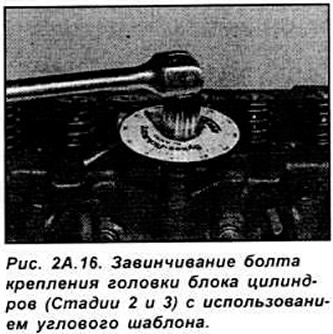

The tightening of the cylinder head bolts is carried out in three stages, in a certain sequence (see fig. 2A.14 - 2A.16)

Lubricate the tappets with clean engine oil, and then slide them into place in the engine. Install the rocker arm shaft assembly and secure it with bolts. Adjust valve clearances. Install the head cover. Perform further operations for installing the cylinder head in the reverse order of removal.

Finally, fill in coolant and engine oil.

Visitor comments