Withdrawal

One of the reasons for removing the cylinder head may be the replacement of the gasket. The presence of defects in the gasket is indicated by a loss of engine power, a decrease in the coolant level with a simultaneous increase in the oil level, and also by the presence of air bubbles in the coolant, which are strongly manifested when the expansion tank cap is removed while the engine is running.

Note: The cylinder head can only be removed when the engine is cold.

Remove the ground wire from the battery. Remove the air filter and disconnect the hoses. On fuel injected engines, remove the air hose from the fuel rail and throttle body. Remove the fuel lines from the cold start valve and fuel distributor, and the hose from the retarder valve.

Drain the coolant from the cooling system and remove the hoses from the thermostat. Remove the coolant supply hoses to the carburetor automatic choke control.

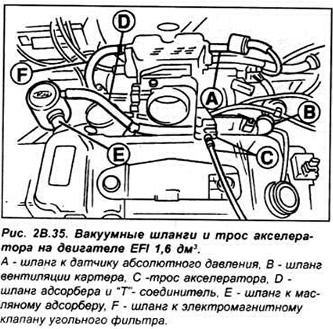

On EFI and SEFI models, disconnect:

- MAP sensor vacuum hose from the top of the intake manifold (EFI models);

- charcoal filter solenoid valve vacuum hose from the top of the intake manifold;

- canister vacuum hose "T"-shaped connector

- brake booster vacuum hose from the top of the intake manifold;

- coolant hose from lug of intermediate injector and in thermostat housing (see fig. 2V.35).

Disconnect the following fuel supply and return hoses:

- on models with a carburetor, disconnect the fuel supply hose from the pump and the return hose from the carburetor.

- on CFI models, disconnect the fuel return hose from the pump section and at the connector.

- on EFI and SEFI models, disconnect the fuel supply hose from the fuel line. Disconnect the return pipe from the fuel pressure regulator.

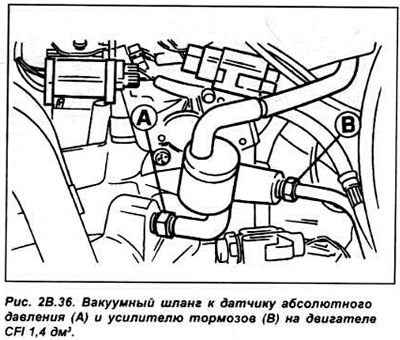

On CFI models, disconnect the brake booster vacuum hose from the intake manifold, the vacuum hose from the MAP sensor, and the carbon filter (see fig. 2V.36).

After noting the location and connections, disconnect the connectors from the following nodes:

- temperature sensor.

- ignition coils.

- coolant temperature sensor.

- radiator fan thermostat.

- carburetor.

- grounding the radio.

- speed sensor.

- fuel injector wiring harness.

- intake air temperature sensor.

On CFI models, separate the throttle control motor, throttle position sensor and injector multi-pin connectors (see fig. 2B.37).

Remove the high voltage wires from the spark plugs, and unscrew the spark plugs.

Turn the crankshaft of the engine until the marks on the camshaft pulley and cylinder head, as well as on the crankshaft pulley and the oil pump housing, are aligned.

Loosen the two bolts securing the toothed belt tensioner and use a screwdriver to move the tensioner away from the belt, compressing the spring, and then tighten the bolts. Remove the toothed belt.

Attention. After removing the belt, it is strictly forbidden to turn the crankshaft and camshaft pulleys, as the pistons may collide with the open valves, which will lead to serious engine damage.

Raise the front of the car and secure it on stands. Unscrew the exhaust pipe from the exhaust manifold. Unscrew bolts of fastening of a head of the block of cylinders in an order of the return to their tightening.

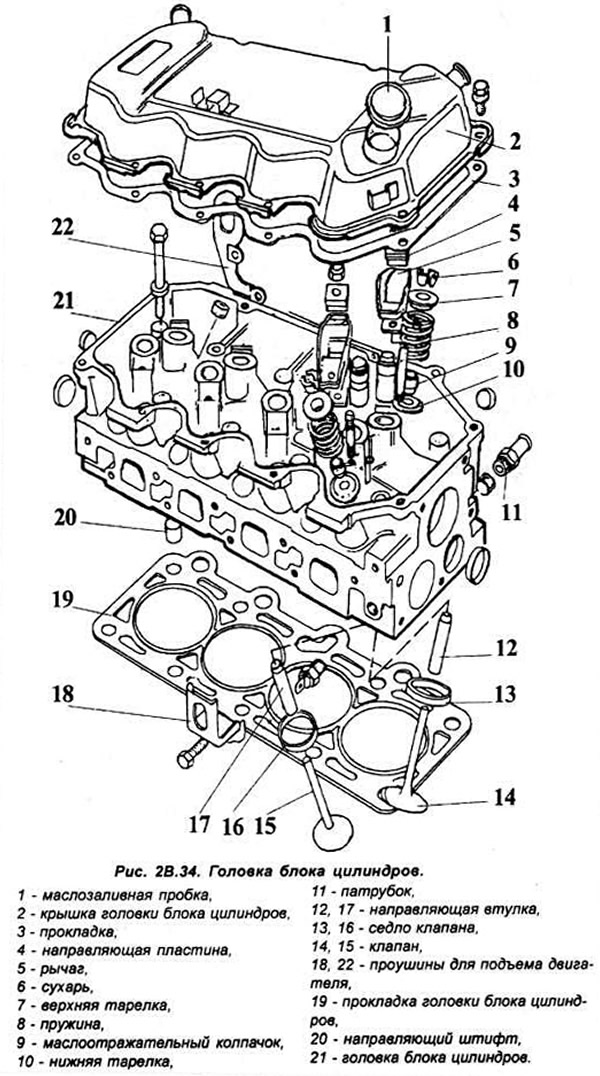

Remove the cylinder head with manifolds. Remove the cylinder head gasket.

Preparing the head for installation

The mating surfaces of the head and cylinder block must be perfectly clean. Use a hard plastic or wooden scraper to clean them. Be careful when cleaning as aluminum alloy is very easy to damage. Check that carbon deposits have not entered the oil and water channels, this is especially important for the lubrication system, since carbon deposits can block the oil supply to engine components. Clean channels if necessary.

Check the mating surfaces of the cylinder head and block for nicks, deep scratches or other damage. If the defects are small, they can be removed by machining, but in case of significant defects, the parts must be replaced.

Using a metal ruler and feeler gauge, check the flatness of the mating surfaces.

Clean the bolt holes in the block. Screwing a bolt into an oil-filled hole can rupture the block due to hydraulic pressure.

Installation

To prevent contact between valves and pistons, turn the crankshaft so that the number one piston is 20 mm below TDC.

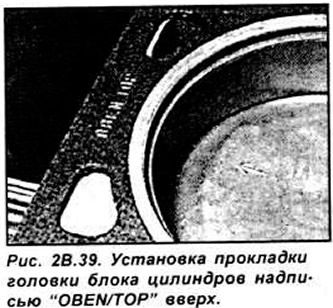

Check that the new cylinder head gasket is the same type as the original and that the marking "TOR" (or "OBEN") upwards Position the new cylinder head gasket on the surface of the cylinder block on the pins Check. that the holes are correctly aligned with the channels of the cooling and lubrication system (see fig. 2V.39).

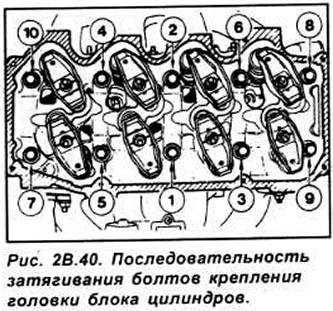

Install the head on the cylinder block, then insert the bolts and tighten them by hand. The tightening of the cylinder head bolts is carried out in four stages, in a certain sequence (see fig. 2V.40).

Install the camshaft pulley so that the TDC mark pointer is aligned with the mark on the front of the head. Turn the engine with a wrench by the crankshaft pulley until the alignment mark on the crankshaft pulley aligns with the TDC mark (0) on the cover of the gas distribution mechanism.

Install the toothed belt on the camshaft pulley, and adjust the belt tension. Further installation is carried out in the reverse order of removal. Add coolant and, if necessary, engine oil.

Visitor comments