Device Features

The control devices are combined into a combination of devices, the connections of which are printed on a flexible board. On cars of the basic configuration, a combination of instruments is installed, including warning lamps for the parking brake, direction indicators, high beam, emergency oil pressure and battery charging, and instruments: a speedometer on the left and a fuel gauge and a coolant temperature gauge on the right. On GL and XR3 vehicles, the instrument layout is almost the same, except that the tachometer is mounted on the right side of the combination, and the fuel and coolant temperature gauges are located in the center of the combination. The speedometer also has daily and total mileage counters.

Control pumps for high beam, emergency oil pressure, charging and parking brake and brake fluid level are centrally located at the top of the combination. In addition, the instrument cluster has a number of warning lights that are switched on by a special electronic unit: brake pad wear, windscreen washer fluid level (lights up with 1/4 remaining), oil level, coolant level remaining 7 liters of fuel. On some cars, an econometer was installed with yellow signal lamps for increased fuel consumption and red for high fuel consumption. In the case of economical fuel consumption, these signal lamps do not light up. The inclusion of each of these signal lamps is carried out by a vacuum sensor.

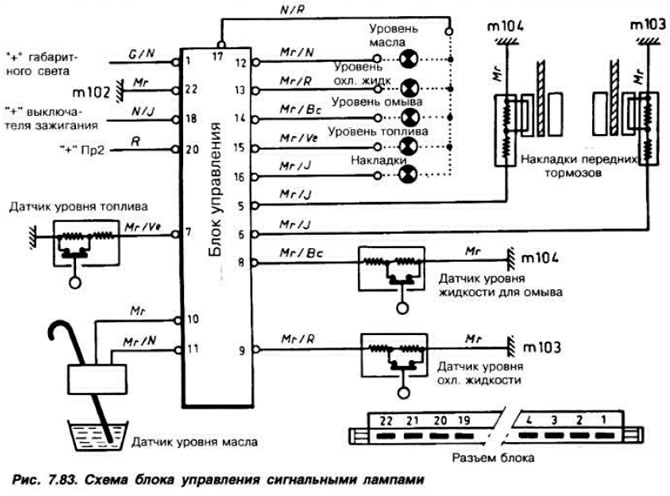

Signal lamp control unit

The VDO brand control unit is located under the instrument panel, it can be accessed through the loudspeaker socket. The unit activates the signal pumps, receiving information from the oil level sensors. washer fluid level, coolant level, fuel level and brake pad wear (fig 7.83).

When the ignition is switched on, the lamps are lit with a constant light for 5 seconds. if the circuits are OK, in the event of an open or short circuit in the circuit, the lamp flashes for 40 seconds and goes out. In the event of a sensor triggering, the corresponding signal lamp lights up continuously until the malfunction is eliminated. integrity of sensor circuits.

The principle of operation of the oil level sensor is based on measuring the resistance of the sensor thread through which a current of 0.20 A passes. The thread resistance is measured every 1.5 seconds. the result obtained is compared with the previous one. If the sensor filament is oil cooled. the resistance remains unchanged. if the thread is not immersed in oil, then it heats up, its resistance changes. the signal lamp lights up. The resistance of the sensor thread is 7.5-8.5 ohms. The washer fluid level and coolant level sensors have a float. the lining wear sensor conductor is pressed into the lining and frays when it is worn, causing the signal lamp to light up. Washer fluid level, coolant level and fuel level sensors continue to measure for another eight seconds in the event of a low level in order to avoid false alarms when the car is rolling.

The resistance value of the level sensors and lining wear is 170-190 ohms at a normal level and 1350-1450 ohms in case of a malfunction. Sensor trigger values:

- fuel level sensor - at least 7l;

- oil level sensor - 3 mm below the mark «Min» oil dipstick;

- washer fluid level sensor - 1/4 level;

- coolant level sensor - label «Min» on the body of the expansion tank;

- brake lining wear sensor - with a lining thickness of 2 mm.

Due to fluctuations in the supply voltage, normal operation may be impaired. To avoid this, it is recommended to connect a 2200-2500 uF capacitor with two insulated poles in parallel with the power supply of the signal lamp control unit, i.e. between terminal 18 (black and yellow wire) and output 22 (brown wire).

Removal and installation of a combination of devices

Disconnect the wires from the battery. Loosen the screws securing the instrument cluster frame (fig 7.84) and pull it towards you, release the two clips and separate it from the instrument cluster.

Loosen the two screws securing the instrument cluster. Remove the lower lining of the bulkhead, release and remove the flexible shaft of the speedometer drive. Carefully remove the instrument cluster by moving it forward and to the side to gain access to the connectors. Disconnect connectors and remove instrument cluster. Before installing the instrument cluster, connect the connectors, install it in place and secure with two screws. Install and secure the frame. Attach the flexible shaft to the speedometer and install the lower front end cover. Connect the battery and check the operation of the devices.

Visitor comments