Weber 2V carburetor

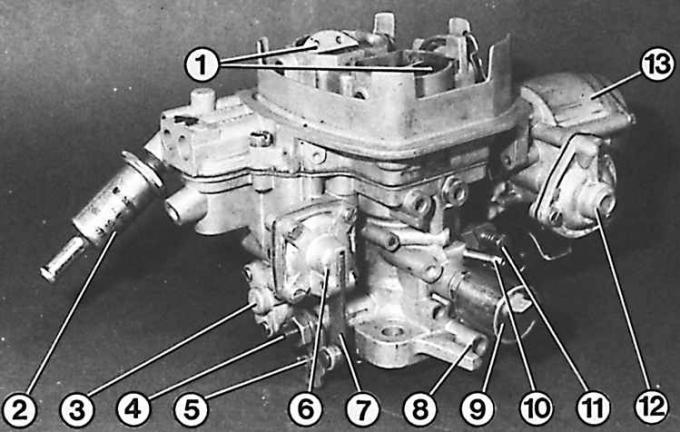

The appearance of the carburetor

1 - air dampers; 2 - fuel filter; 3 – economizer; 4 - axis of the primary chamber; 5 - accelerator pump drive eccentric; 6 - accelerating pump; 7 - lever drive accelerator pump; 8 - screw for adjusting the quality of the mixture; 9 – the electromagnetic valve of system of idling; 10 - vacuum fitting to the ignition distributor; 11 - idle speed adjustment screw (amount of mixture); 12 - cold start device; 13 - starting device

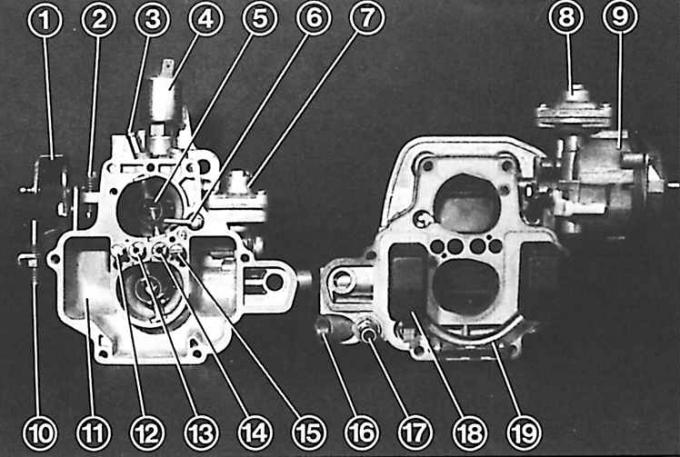

Carburetor with cap removed

1 - throttle actuator lever; 2 – the screw of adjustment of turns of idling (amount of mixture); 3 - vacuum fitting; 4 – the electromagnetic valve of system of idling; 5 - mixing chamber; 6 – a tube of the accelerating pump; 7 - accelerating pump; 8 - cold start device; 9 - starting device; 10 - screw maximum speed; 11 - float chamber; 12 - idle jet of the secondary chamber; 13 - main and air jets; 14 - main and air jets of the primary chamber; 15 - idle jet of the primary chamber; 16 - fuel input; 17 - fuel return; 18 - float; 19 - lever floats

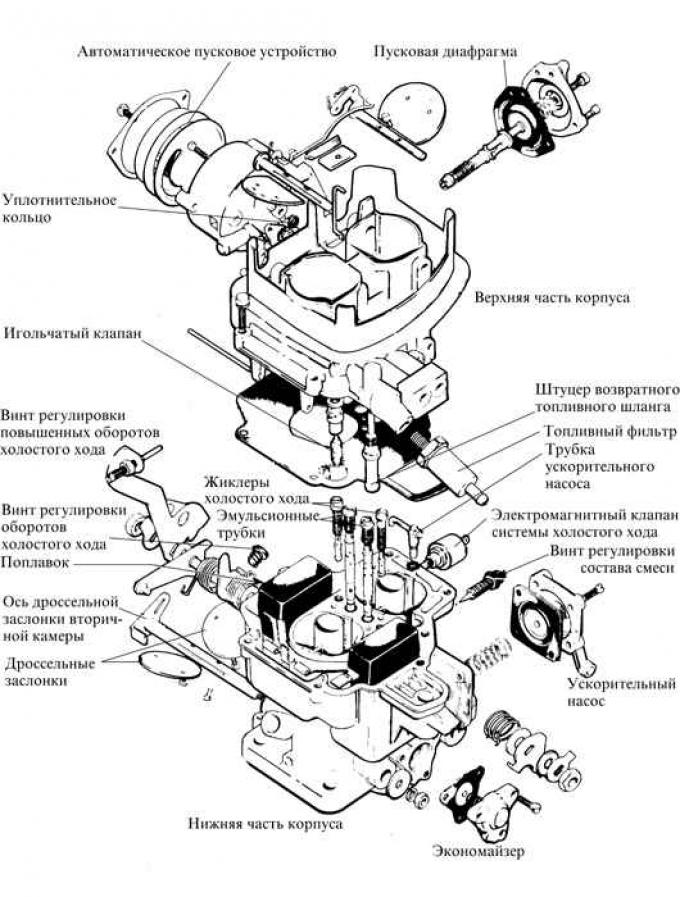

The carburetor body consists of two cast parts. The upper half contains the float chamber cover, float hinges, fuel inlet and outlet fittings, fuel fine filter, spring-loaded needle valve, dual air intake, air dampers and part of the vacuum-controlled economizer valve.

In the lower half of the body is placed a float chamber, an accelerator pump, two diffusers with sprayers, throttle valves, levers, jets and an economizer valve.

Throttle valves are arranged in such a way that the primary opens first, and then the secondary follows, so that both valves are fully open at the same time.

The diffuser of the first chamber, throttle and atomizer are smaller than the secondary ones, while the dimensions of the diffuser of the first and second chambers are the same.

All mixture systems are located in the lower half of the carburetor body, and the main metering systems operate in both chambers, while the idle and economizer valve systems operate only in the primary chamber, and the mixture enrichment system in the secondary chamber.

The accelerator pump sprays fuel into the diffuser.

A fitting is installed on the lower half of the housing to control the vacuum ignition timing controller.

The carburetor has a fully automated choke type choke for easy cold starting.

Visitor comments