Attention! The fuel pump is particularly sensitive to dirt and water inclusions in the fuel.

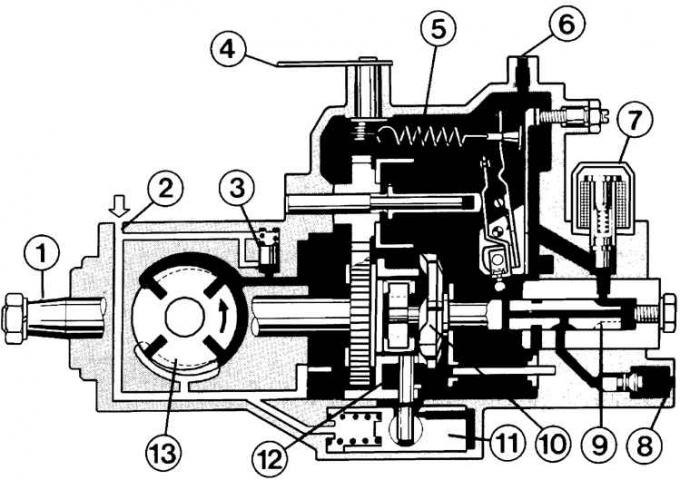

High pressure fuel pump

1 - drive shaft; 2 – fuel input; 3 - safety valve; 4 – control lever; 5 – centrifugal regulator; 6 - calibrated fuel return hole; 7 - solenoid valve; 8 – fuel outlet to injectors; 9 - piston-distributor; 10 - disk cam; 11 - injection advance clutch (conventionally rotated by 90°); 12 - roller; 13 - rotary pump (conventionally rotated by 90°)

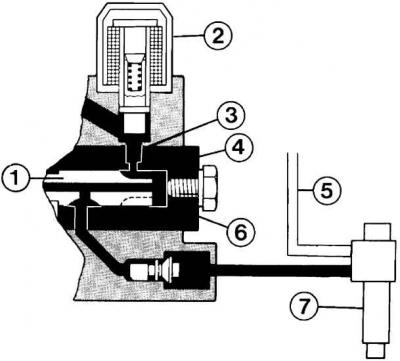

Fuel supply to the control piston

When turning the control piston (1), filling hole (3) located under the control slot (4), which is a recess in the control piston. Fuel, which is supplied under pressure by a rotary pump, enters the high pressure chamber (6) in front of the distribution piston and completely fills the chamber; 2 - solenoid valve, 5 - fuel return pipeline, 7 - nozzle.

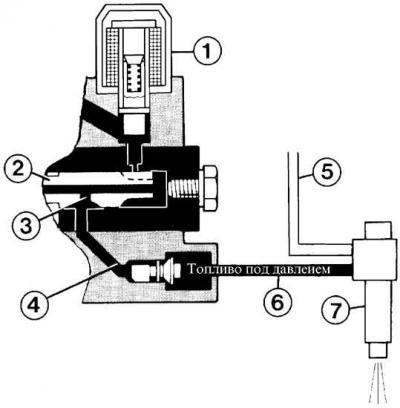

Fuel injection

After filling with fuel, the control piston (2) continues to rotate and closes the filling hole. At the same time, the protrusions of the disk cam run into the rollers of the roller ring and the distributor piston begins to compress the fuel. At this point, the distribution channel (3), with simultaneous rotation of the piston, is located so that it is combined with the outlet channel (4). Now through the injection pipeline (8) fuel is supplied to the injector (7) and injected into the cylinder. Remaining fuel in the return pipeline (5) enters the fuel tank. Solenoid valve (2) must be open, as fuel flows through it to the distributor piston.

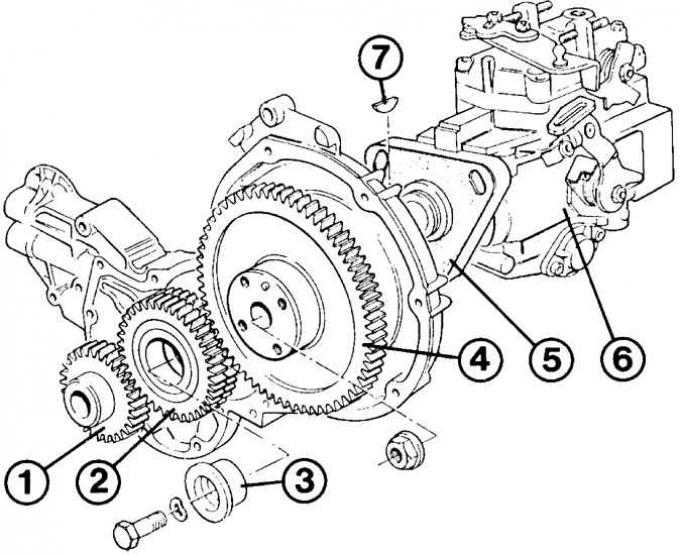

High pressure fuel pump drive

1 - crankshaft drive gear; 2 - intermediate gear; 3 - bearing sleeve; 4 – a gear wheel of the fuel pump; 5 - flange; 6 - high pressure fuel pump; 7 - key

Visitor comments