Examination

Erratic idle stalling or backfiring may be caused by damage to the air pulsation system.

Inspect the vacuum pipe for cracks and other defects along its entire length. Replace pipe if necessary.

Inspect the air filter housing and piping.

If there is a suspicion of a malfunction of the air pulsation valve, disconnect the electrical connector and remove the vacuum hoses from the valve. Connect the accumulator to the valve with an additional wire and check that air passes through the valve. When the accumulator is disconnected from the valve, air must not pass through the valve.

Replacing the air filter and housing on CVH engines

Remove the air filter cover and remove the filter element (see fig. 4E.23).

Installation is made in sequence, return to removal.

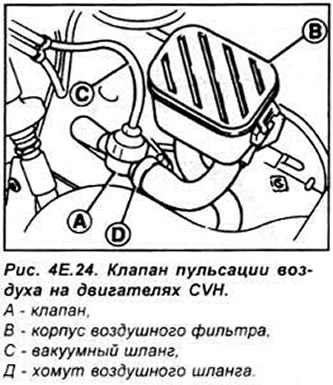

Replacing the air pulsation valve on CVH engines

Remove the negative terminal from the battery.

Disconnect the vacuum hoses from the valve (see fig. 4E.24).

Loosen the air hose clamp and separate the hose from the valve.

Disconnect the second air hose from the valve. At the same time, pay attention to the orientation of the valve and remove it from the car.

Installation is made in sequence, return to removal.

Replacing the Air Pulsation Control Valve on CVH Engines

Remove the negative terminal from the battery.

Disconnect the air hoses from the control valve (see fig. 4E.25).

While holding the bottom pipe nut 8 of the valve base with a wrench, unscrew the valve by the valve nut with a second wrench.

Installation is made in sequence, return to removal.

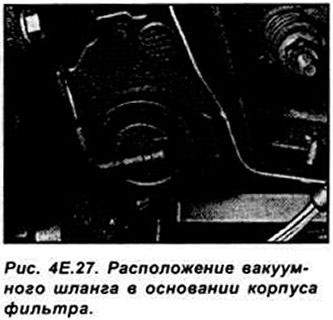

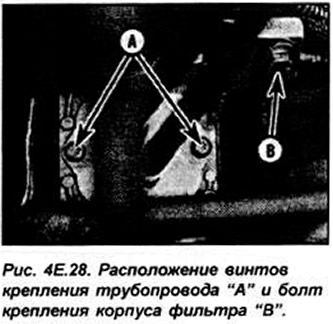

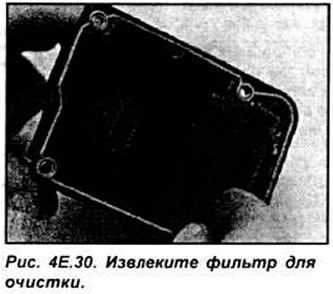

Replacing the air pulsation valve, filter and housing on Zetec engines

Remove the negative terminal from the battery. Raise the front of the car and secure it on stands. Disconnect the vacuum hose from the base of the filter housing (see fig. 4E.27).

Remove the engine air supply pipe system. Loosen the housing fixing screws and remove it (see fig. 4E.28).

To remove the filter housing, unscrew 4 screws and remove the cover from the housing. Remove the filter and clean it in an appropriate solvent (see fig. 4E.29, 4E.30).

Installation is carried out in 8 sequences, reverse to removal.

Replacing the air pulsation solenoid valve

Remove the negative terminal from the battery. Remove the electrical connector. Remove the valve from the suspension. Mark and disconnect from the valve vacuum hoses. Installation is made in sequence, return to removal.

Replacing the air pulsation piping on HCS and CVH engines

Remove the negative terminal from the battery. Remove the air filter for better access. Disconnect the vacuum hose from the valve.

Unscrew the bolt and remove the pipe connecting the exhaust manifold, cylinder head and gearbox.

Unscrew the 4 nuts securing the air injection pipes to the intake ports of the cylinder head and remove the entire injection pipes (see fig. 4E.31).

Thoroughly clean the discharge pipes and remove all traces of corrosion to ensure tight connections after installing the pipes. Installation is made in sequence, return to removal.

Replacing the air pulsation piping on Zetec engines

Remove the negative terminal from the battery. To improve access, remove the air supply pipe system to the engine.

Unscrew the bolt securing the heat-resistant shield of the exhaust manifold. Raise the front of the car and secure it on stands. Disconnect the vacuum hose at the base of the air filter housing. Unscrew the 2 bolts securing the pipe to the suspension and 4 nuts securing the pipes to the intake manifold. Remove the pipes and the entire filter housing (see fig. 4E.32).

Thoroughly clean the pipeline and remove all traces of corrosion to ensure leak-tight connections after installation of the pipeline.

Installation is made in sequence, return to removal.

Visitor comments