2. Disconnect the negative battery cable.

3. Remove the air cleaner assembly.

4. Remove drive belts (Chapter 1).

3.0L - front head

5. Remove the Main Drive Belt Kit with Tensioner (Chapter 1).

6. If available, remove the nuts securing the power steering pump. without disconnecting the hoses.

7. Remove coil bracket (chapter 5) and ground wire.

3.0L - rear head

8. Remove engine support bracket (generator adjustment bracket).

9. Remove the ground wire from the engine lifting lug. remove the bolts from the throttle wire support bracket at the opposite end of the head.

3.8L - front head

10. Remove generator and bracket (chapter 5).

11. Remove the power steering pump (if available), without disconnecting the hoses.

12. If there are air conditioning systems, then separate the system compressor from the mounting bracket without disconnecting the hoses. Set it aside.

Warning: do not disconnect the air conditioning hoses without a specialist.

3.8L - rear head

13. Disconnect the air intake bracket from the rear of the cylinder head.

14. Remove the drive belt tensioner kit.

15. Remove the air intake pump to the exhaust manifold (chapter 6).

For all engines

16. Remove the intake manifold (section 6).

17. Remove the exhaust manifold (section 7).

18 Remove the cover (And) valve mechanism (section 3).

19. Loosen the hinge pin bolts enough to remove the valve levers from the push rods and turn them to the side.

20. Remove push rods (section 4).

21. Remove the head bolts and lift the cylinder head (see picture). When removing the front head from the 3.0L engine, lift it over the centering pins and pull towards the gearbox to remove the power steering pump studs from the bracket (see picture). Set the pump aside so that no liquid flows out of it.

22. Carefully remove all gasket residues with a scraper and clean parts with solvent. Remove traces of oil with a cloth soaked in acetone or lacquer thinner. Chapter 2 parts C describes the procedures for checking cylinder heads.

23. Use an appropriately sized tap to rethread the head bolt holes. On 3.0L engines, thread the head bolts with a die. New bolts are required on 3.8L models. Lubricate the bolt threads with oil other than those specified below.

24. Recheck the bolt holes in the cylinder head and block and the cylinder bores for coolant, oil and other contaminants. Remove the assembly if necessary.

25. Install a new gasket on the guide pins of the block. The top of the gasket should have a TOP stamp (TOP) or THIS SIDE UP (this is the top side), to install it correctly (see picture) Do not use sealant when installing the gasket.

Note: On 3.8L and 3.0L engines from 1992 onwards, the bolts must be changed each time the head is installed. Apply a thin layer of sealant (type Ford D8A2 - 19554 - A or similar) on the threads of the short bolts of the cylinder head (closest to the exhaust manifold).

26. Tighten the head bolts by hand.

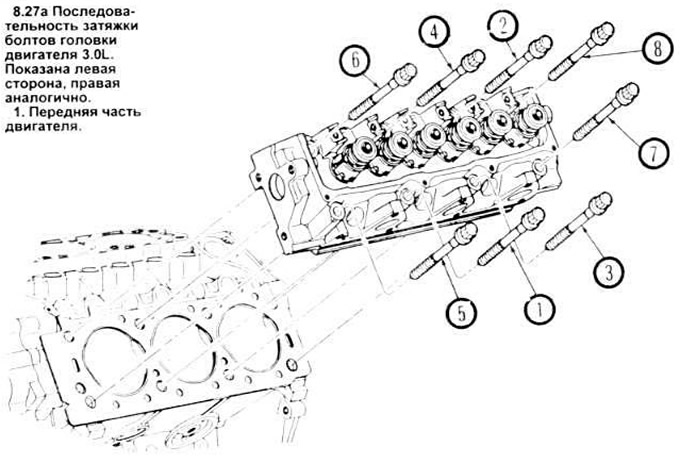

27. According to the specified sequence (see picture), tighten the head bolts in several steps to the required torque.

28. For 3.8L engines only - loosen the head bolts 2-3 turns and tighten them again in the same sequence to the same torque value.

Note: with the same tightening option, there is no need to re-tighten these bolts after working on the engine. However, if you wish, you can always check the tightening torque values.

29. Reassemble the removed parts in the reverse order of disassembly. Lubricate valve parts with high viscosity engine oil.

30. Install the push rods each in its place. At the same time, turn the crankshaft for each valve until the pusher is at its lowest point. Install the valve levers, pivot pins and bolts. Tighten to the required torque. Then repeat with the remaining valves.

31. Fill cooling system, change oil and filter (Chapter 1). start the engine Check the ignition timing and any leaks.

32. If anything has been replaced or the valves have been lapped, then check the valve clearances as described in section 4.

Visitor comments