Checking the oil level

Carry out the check at the operating temperature of the oil. Park the vehicle on a level surface, apply the parking brake and depress the brake pedal. With the engine idling, move the selector lever three times in sequence to all positions. Then set the selector lever to the position «R» and wait at least one minute. With the engine running, remove the dipstick and check the oil level. which should be between the two marks. If necessary, add oil through the dipstick tube. Dark brown or black oil is a sign of worn clutches or band brakes.

Checking the selector cable adjustment

Set selector lever to position «D» and hold it in that position. Loosen the nut securing the cable to the selector lever on the gearbox and make sure that the lever axis is in the position «D», tighten the nut.

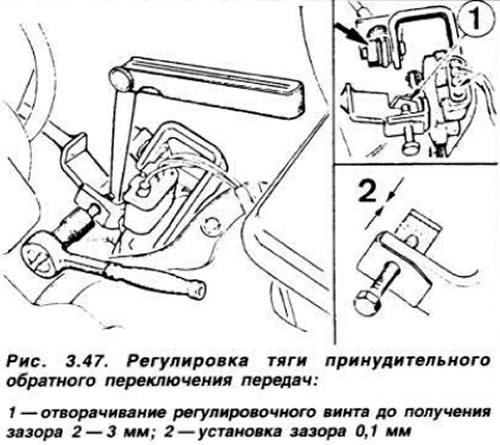

Checking the thrust of the forced reverse gear shift

Loosen adjusting screw 1 (pic. 3.47), mounted on the axis of the gearshift valve so that a gap of 2-3 mm is formed between it and the stop.

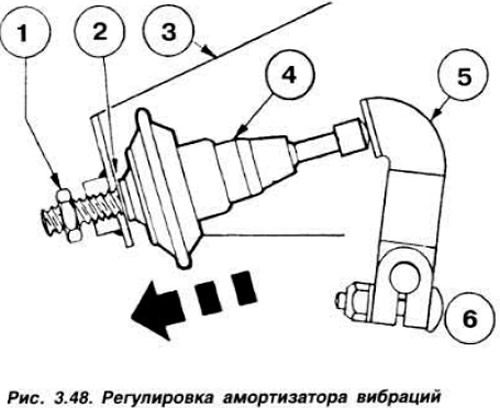

Check and, if necessary, adjust the idle speed of the engine. Tighten the adjusting screw, leaving a gap of no more than 0.1 mm between it and the stop. Adjust vibration damper (pic. 3.48).

To do this, turn the shock absorber until a gap of 2 mm is obtained (pos. 2), by measuring it with a feeler gauge. Move the drive lever 5 to the plastic tip of the shock absorber 4. Fasten the lever in this position with a screw and nut 6. Lock the shock absorber with a nut 1 Mark the position of the shock absorber and tighten it four turns to create a preload. Total clearance including the previous 2mm. should be 7 mm. Tighten nut 1 for shock absorber blocking.

Oil pressure check

Unscrew the plug on the front wall of the box crankcase, under the flange of the valve box cover. Screw the hose fitting of test pressure gauge 17.014 into the hole and measure the oil pressure at idle speed and with the accelerator pedal fully depressed with the parking brake fully applied (no more than 5 sec) for all positions of the selector lever. The pressure must be as specified in table 3.4. Disconnect the pressure gauge, reinstall and tighten the plug.

Visitor comments