Warning: Do not attempt to repair the brake master cylinder if the vehicle is a 1990 with ABS (anti-lock braking system). See section 18.

Withdrawal

1. Place a rag under the pipe ends, prepare caps and plastic plugs for them.

Caution: brake fluid destroys paint. Cover all parts of the body and be careful not to spill brake fluid while working.

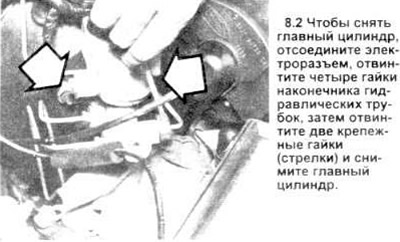

2. Unscrew the nuts from the pipes at the ends of the pipelines where they enter the master cylinder (see picture).

3. Pull the lines slightly away from the master cylinder and cap the ends to prevent leaks.

4. Disconnect the electrical contact of the brake light switch, unscrew the two nuts securing the master cylinder, remove the master cylinder from the vehicle.

5. Remove the tank cap, drain the remaining liquid in the tank.

Bulkhead

6. Place the master cylinder in a vise so that the jaws grip the support flange.

7. Depress the piston and remove the retaining ring with special pliers (see picture).

8. Remove the main piston block from the cylinder bore (see picture).

9. Remove the secondary piston assembly from the cylinder. You may have to take the cylinder out of the vise and turn it over, gently tapping on a piece of wood to remove the piston (see picture).

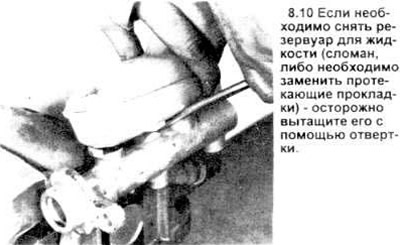

10. If fluid leaks through the o-rings, use a screwdriver to pry the reservoir out of the cylinder body (see picture). Remove spacer rings.

11. Corrosion and damage are possible in the cylinder bore. If they are, it is necessary to replace the brake master cylinder with a new one, since abrasive materials cannot be used in the cylinder bore.

12. Lubricate new gasket rings with silicone grease and insert into the master cylinder housing. Make sure they are installed correctly.

13. Lay the reservoir on a hard surface and, applying pressure from above, rotate the master cylinder body onto the reservoir.

14. Lubricate the cylinder bore and the primary and secondary pistons with clean brake fluid. Install the secondary piston assembly into the cylinder (see picture).

15. Install the main piston in the cylinder bore, lower it and install the retaining ring.

16. Inspect reservoir cap and diaphragm for cracks or deformation. Replace damaged parts.

17. Note: When removing the master cylinder, drain the hydraulic system. Drain time can be reduced when the cylinder is filled with fluid and the vehicle has a drain pan underneath (paragraphs 18 to 25).

18. Screw threaded plugs of the appropriate size into the outlet holes of the cylinder, fill the reservoirs with brake fluid. The cylinder must be installed so that the liquid does not overflow during release.

19. Pull out the plugs one at a time, starting with the rear holes closest to the amplifier), push the piston into the bore to purge air from the master cylinder. To prevent air from being drawn back in, the corresponding plug must be replaced before the piston is returned to its original position.

20. The piston should make three or four strokes to each hole to be sure that all the air has been expelled.

21. Since high pressure must be applied in the release procedure, it is acceptable to remove and replace the plug with each stroke of the piston. Before pushing the piston, remove one of the plugs completely. However, before opening the piston, instead of replacing the plug, firmly pinch the hole with your finger to prevent air from flowing back into the master cylinder. Wait a few seconds for the brake fluid to flow from the reservoir into the piston bore, then repeat the procedure. Going down under pressure, the piston "blow away" finger from the hole, displacing air from the inside. Only when brake fluid comes out of the hole, replace the plug and move on to the next hole.

22. Refill master cylinder reservoirs, install diaphragm and cap.

Installation

23. Carefully install the master cylinder in reverse order of removal, then bleed the brakes (see section 11).

Visitor comments