Examination

1. Loosen the wheel nuts, raise the car, place it securely on stands. Remove the wheel and re-tighten the two nuts to hold the disc in place.

2. To separate the caliper and steering knuckle, look at the first few paragraphs in section 2. Because it's part of the pad replacement procedure.

Warning: do not let the caliper hang on the brake hose and do not disconnect the hose from the caliper (see picture).

3. Visually inspect the disc surface for nicks or other damage. Small scratches and narrow grooves are normal for a used disc and are not essential for disc replacement. Deep scratches - more than 0.38 mm (0.015 inch) - require removal and processing of the disk. Check both sides of the disc.

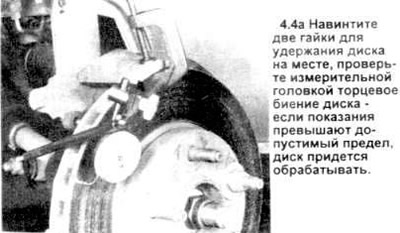

4. To check disc end runout, connect an indicator (measuring head) to the steering knuckle and install the leg at a distance of 12.7 mm (1/2 inch) from the edge of the disc (see picture). Set the indicator scale to zero and turn the dial. Indicator readings should not exceed 0.076 mm (0.003 inch). If more, then the surface should be treated.

Note: it is recommended to process brake discs regardless of the indicator (to get a smooth, flat surface that will prevent brake pedal pulsation and other unwanted symptoms.

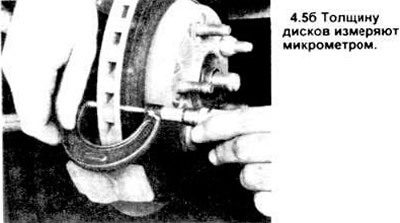

5. When processing a disk, it is necessary to ensure that its thickness does not become less than the maximum permissible value, the value of which is stamped on the edge of the disk itself (see picture). Disc thickness can be checked with a micrometer (see picture).

Removal and installation

6. Unscrew the two nuts holding the disc in place, remove it from the hub.

7. Installation is carried out in the reverse order.

Visitor comments