Examination

1. The manufacturer does not regulate the test of the stator (sensor) TFI systems - IV. If the system does not work with the ignition unit in good condition, replace the stator.

Replacement

2. Remove the distributor cap and set it aside along with the wires.

3. Disconnect the TFI module from the wiring.

4. Remove the distributor (see section 7).

5. Remove the slider (if necessary see chapter 1).

6. Remove the ignition block (section 9). To protect it from possible damage during disassembly of the distributor.

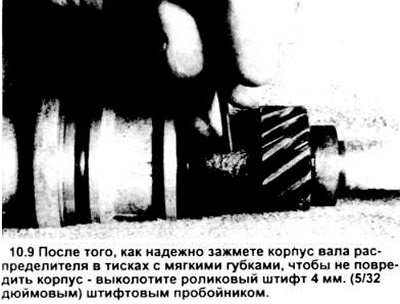

7. Clamp the lower end of the distributor in a vice with soft jaws.

8. When removing the drive gear, remember that the roller pin is slightly misaligned. When installing the distributor, the roller pin cannot be installed until the holes in the drive gear and the distributor shaft into which it is inserted are completely aligned.

9. Using a punch with a diameter of 4 mm (5/22"), knock out the roller pin from the shaft - the assistant at this time should hold the distributor in a vice (see picture).

10. Open the vise and place the distributor so that the drive gear is at the top.

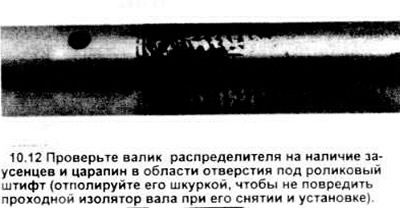

11. Using a puller, remove the drive gear (see picture).

12. Before disconnecting it from the distributor, check the shaft - there may be burrs or scratches from the assembly, especially around the roller pin hole (see picture). If there are burrs or scratches, polish the bead with sandpaper and wipe thoroughly to avoid damaging the seal lips and bushing on the distributor base.

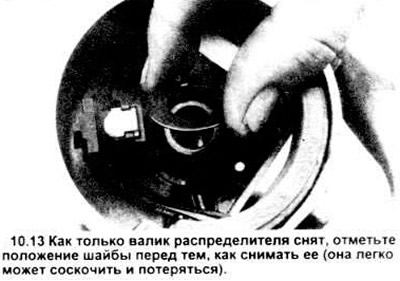

13. After clearing any burrs and scratches, remove the roller assembly by pushing it into the plate. Note the location of the intermediate ring washer in relation to the distributor base before removing this washer (see picture).

14. Unscrew the locking screw of the thrust of the octane corrector (see picture).

15. Lift the inner end of the rod out of the stator retainer (see picture) and push the octane corrector rod out of the distributor base.

Note: Do not lose the o-ring from the link hole. It protects the distributor elements from contamination.

16. Remove the two stator screws (see figure 10.15).

17. Carefully lift the stator assembly straight up and off the distributor.

18. Check the shaft bushing at the base of the distributor for wear and signs of overheating if there are signs of wear and (or) damage, replace the entire distributor assembly.

19. Check the O-ring at the base of the distributor. If it is damaged or worn, remove it and install a new one (see picture).

20. Check the cast housing - there may be cracks, wear. For any obvious damage, replace the distributor assembly.

21. Place the stator on the roller bushing and press it into the distributor housing until it fits snugly into its seat.

22. Install the stator screws and tighten securely.

23. Insert the octane corrector rod into the hole in the base of the distributor, push its inner end into the rack.

Note: make sure that the hole for the rod is closed with an o-ring.

24. Screw in and securely tighten the octane corrector rod screws.

25. Apply a light coat of engine oil to the distributor shaft and thread the shaft through the bushing.

26. Install the distributor in a vise with the lower end up. Place a clean rag between the distributor base and the vise jaws to protect the distributor base. Place a wooden block under the distributor shaft - it will support the shaft and prevent it from falling out when installing the drive gear.

27. Using the paint marks that were made on the drive gear and distributor shaft housing, turn the shaft until the hole in the drive (and, accordingly, marking with paint), the hole in the shaft and the paint mark on the distributor shaft will not line up.

28. Using a hammer and a deep socket, carefully push the driving gear back onto the distributor shaft (see picture). Make sure that the hole on the driving actuator and the shaft match up. Since these two holes were drilled from the same installation at the factory, they must be completely aligned otherwise the locking pin cannot be installed (see picture).

29. Once the gear is tight "villages" into place and the holes are aligned, turn the distributor on its side in a vice, and using a 4 mm punch (5/32") install a new pin in the drive.

Make sure neither end of the pin protrudes from the drive gear.

30. Check the smooth rotation of the distributor shaft, then remove the distributor assembly from the vise.

31. Install the TFI - IV module (see section 9).

32. Set the slider (if necessary see chapter 1).

33. Install the distributor (see section 7).

Visitor comments