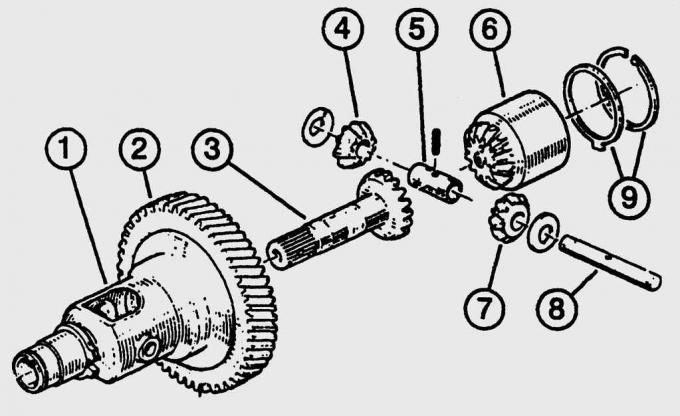

Pic. 12.11. Main gear and differential box: 1 - differential box; 2 – a conducted gear wheel of the main transfer; 3 - output shaft and side gear; 4, 7 - satellites; 5 - pin satellites; 6 - side gear; 8 - the axis of the satellites; 9 - intermediate and retaining rings

The main gear is designed to convert the rotational speed of the secondary shaft into the corresponding frequency of the wheel drive shafts and, due to the differential, provides different rotational speeds of the inner and outer drive wheels when cornering (pic. 12.11). The final drive gear is bolted to the differential box. The drive shafts form a force-locking connection between the final drive and the wheel hub.

Main gear and wheel drive shafts

Main gear.

Placed together with the differential and manual transmission or automatic transmission CTX in a common crankcase. In the differential box, four bevel gears are in constant engagement, two of which are connected to the drive shafts.

Movement straight.

The front wheels rotate synchronously with the main gear. The differential rotates at the same frequency, the bevel gears are in relative rest.

Turning movement.

A wheel located on the outer turning radius travels a longer distance than a wheel located on the inner turning radius (speed difference). If this difference is not compensated, the car will skid hard and the spinning inner front wheel will not fit into the turn.

Differential -

serves to distribute torque between the wheels and allows the wheel drive shafts to rotate at different angular speeds. Side gears and satellites in the differential box provide the required compensation for different angular speeds of the drive wheels. The speed of the side gear connected by the drive shaft to the wheel at the outer turning radius is somewhat greater than the speed of the differential box, as a result of which the satellites begin to rotate, which in turn reduce the speed of the side gear connected to the wheel moving along the inner radius. The difference in the angular speeds of the side gears compensates for the difference in the distance between the two front wheels.

Power transmission to the wheels (from differential).

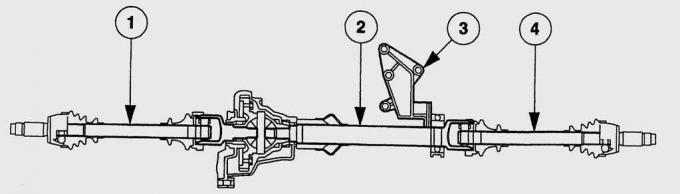

Pic. 12.12. Wheel drive shafts: 1 - left drive shaft; 2 - an intermediate shaft with a support bearing; 3 - cast iron bracket; 4 - right drive shaft

Although the Fiesta's gearbox housing is mounted offset from the longitudinal axis of the vehicle, the length of both drive shafts is the same. The right drive shaft is connected to the output flange of the gearbox through the intermediate shaft (pic. 12.12).

Synchronizing joint.

The constant velocity joints of the drive shafts transmit torque evenly with any movement of the rear suspension. They contain balls that roll along a special spherical treadmill, depending on the movement of the front suspension. Thus, a uniform drive of the front wheels is ensured, regardless of the deflection of the drive shaft along with the suspension. CV joints have virtually no effect on the steering wheel. In the Fiesta, a removable joint is installed on the gearbox side near the drive shafts, and on the wheel side, the joint is rigidly fixed to the drive shaft.

Wheel hub.

The front wheel hub is mounted in the steering knuckle on two ball bearings. The outer hinges of the drive shafts are splined to the front wheel hubs. In the gearbox housing, the drive shafts are splined to the side gears of the differential. The backlash between the box and the drive shaft is eliminated by the location of the splines. The splines in the gearbox are straight, the splines on the shaft are made at a slight angle. The different splines provide a connection with a preload, i.e. fixed landing, excluding all adjustments.

PRACTICAL ADVICE

Drive shaft noise

Usually there are no problems with the drive shafts, but their service life depends on how you drive the car. Intensive wear of the shafts leads to frequent sharp acceleration of the car with wheel slip when the front wheels are fully turned.

CV joints of drive shafts can make noises that disappear and then reappear. Silent operation can continue even for several days.

Characteristic noises, which are rhythmic beats or crunches when the accelerator pedal is depressed and coasting (can be changed by turning the steering wheel), indicate a fault in the wheel-side joint.

This also applies to a vibrating steering wheel when cornering.

Clicking knocks when starting off with the wheels turned may indicate a malfunction of the drive shaft.

WARNING

Often similar symptoms indicate wheel bearing failures.

Visitor comments