Air conditioning system

Warning: The air conditioning system is under high pressure. Do not loosen hose ends or move parts before pressure has been relieved by an air conditioning technician. In any case, ensure eye protection when disconnecting system piping.

1. To ensure that your air conditioner is operating at maximum efficiency, the following checks should be carried out regularly.

A) check the condition of the compressor drive belt. Replace it if it is worn or damaged (see chapter 1).

b) check drive belt tension and adjust if necessary (see chapter 1).

V) check system piping. Possible cracks, bubbles. hardening and deformation of hoses. Check hoses and fittings for oil bubbles and leaks. If there is visual wear, damage, or leaks, replace the hoses.

G) check the condenser plates - there may be leaves, insects and other foreign objects that have passed into the condenser on their own. enjoy "condenser comb" or compressed air to clean it of debris.

d) check that the coolant charge in the system is normal.

2. Not bad at least once a month to boot the system for 10 minutes. This is especially important during the winter months when prolonged exposure to low temperatures can cause hardening and consequent failure of the seals

3. Due to the complexity of the air conditioning system and equipment for its maintenance, the issues of serious diagnostics and its restoration are beyond the scope of this book. However, this chapter provides a number of simple checks and procedures for replacing system components.

4. The most common cause of insufficient cooling is a lack of coolant in the system. If the efficiency of the system has noticeably decreased, then one of the following will help you determine the coolant level "fast" checks.

For valve systems with a dry-expanding type receiver

5. Warm up the engine to normal operating temperature.

6. Set the air conditioning temperature selector to the maximum "cold" mark and the blower to the upper mark of the scale. Open car doors (so that the air conditioning system does not turn off immediately after reaching the required temperature in the cabin).

7. Look through the viewing window (if it exists). If the coolant foams, then it is not enough. Charge the system (see below).

8. If there is no viewing window, feel the compressor inlet and outlet tubes. One side should be cold and the other hot. If there is no significant difference in the temperature of the tubes, then something is wrong with the compressor or the system itself. Including, perhaps, the absence of a charge. Further deeper testing is beyond the scope of this guide.

For tube type systems with accumulators/holes

9. Warm up the engine to normal operating temperature.

10. Set the air conditioning temperature selector to maximum "cold", and the blower - to the upper mark. Open car doors (so that the air conditioning system does not turn off immediately after reaching the required temperature in the cabin).

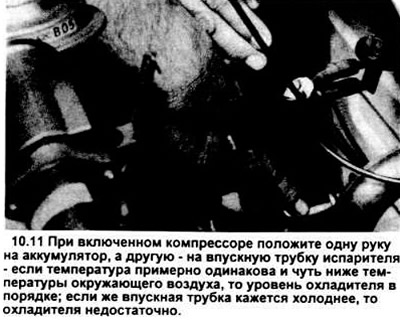

11. Having activated the compressor - the clutch will make a characteristic click and its center will begin to rotate, touch the evaporator inlet pipe between the hole and the battery with one hand and lower the other hand on the battery casing (see picture).

12. If the temperature of both surfaces is approximately the same and slightly less than the ambient temperature, then everything is in order with the cooler level. A more detailed study is beyond the scope of this book and should be carried out by specialists.

13. If the inlet tube freezes or is colder than the battery surface, then the coolant charge is low. Add it as below.

Adding coolant (for all systems)

Note: At the time of writing this manual, the procedure described below complies with the standards. usually the cooler comes in larger containers (30 pounds). If you decide to add coolant from large tanks. You will need a set of dipsticks, various tips, adapters and hoses, as well as the Haynes Manual for Air Conditioning and Heating Systems.

Warning: a number of 1992 models are equipped with systems that consume R134 refrigerant. They can be identified by yellow labels on parts that say "NON CFC". The compressor clutch on systems with R134 refrigerant is gold. Do not confuse these systems and do not add the wrong refrigerant to them.

14. Purchase a charging kit. The kit includes two to three 14 oz cans of coolant, a threaded valve, and a short length of hose that connects to the threaded valve at one end and the other end to the system valve on the underside of the system. One of the containers must contain a cooler with red dye. If there are leaks in the system, the red dye will help you locate the leak. Do not add more than three containers at the same time.

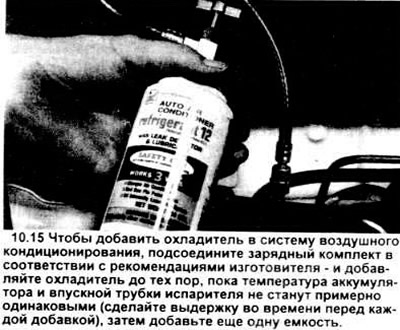

15. Connect the charging kit according to the manufacturer's instructions (see picture).

Warning: never connect the charging kit to the top wall of the system.

16. Warm up the engine, turn on the system.

17. If the system is battery type:

A) add coolant from the bottom of the system until the surface of the accumulator and the evaporator inlet tube are equally heated. Let the temperature stabilize before each new coolant addition.

b) after the surface temperatures of the accumulator and the evaporator inlet pipe become the same, add the rest of the contents of the container.

18. If you have a receiver-drier type system in your car, put a thermometer in the hole in the dashboard closest to the evaporator and add coolant until the thermometer reads about 5-7 degrees Celsius (40-45 degrees Fahrenheit).

Heating system

19. If the air coming out of the heater vents on the dashboard is not hot enough, this may be due to the following reasons:

A) thermostat stuck open.

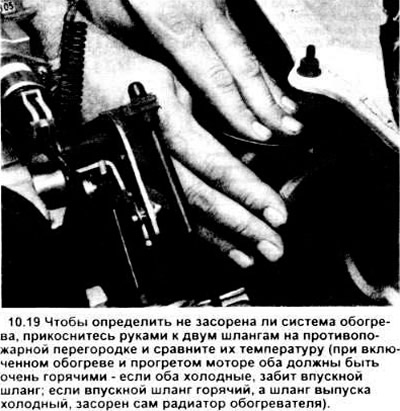

b) the heater hose is blocked preventing coolant from reaching the heater core. Feel both hoses on the firewall (see picture). They must be hot. If one of them is cold, then there is a malfunction in either one of the hoses, or the heater radiator itself, or the valve is clogged. Disconnect the hoses and either blow out the radiator with compressed air or flush it with water. If this does not clear the blockage, then remove both hoses and blow them out with compressed air.

V) if the heater still does not supply hot air, the heater core must be replaced (see section 13).

20. If the rotation speed of the fan motor does not correspond to that indicated on the switch, then the fuse is damaged, the resistance of the fan motor burned out, or the motor itself is faulty

A) always start the test with a fuse.

b) check the voltage at the fan motor leads.

V) Pull out the heating/air conditioning control assembly until you can check with a test lamp or tester that there is voltage at the control assembly switch (see picture). If there is no voltage, check the wires from the battery to the switch (see wiring diagrams at the end of the book).

G) the fan motor resistance is located just behind the glove box (see section 12). After checking the resistance, make sure that voltage is applied to it from the switch

- 1. If the resistance is de-energized, check the wires.

- 2. If the wires are OK, replace the switch (see section 11).

d) Using a test lamp or tester, determine if the fan motor is receiving pi voltage. If there is no voltage, replace the resistance (see section 12).

21. In case no air comes out of the vents, listen for most motors to make noise when running.

A) if you can't hear the engine noise (and the switch and resistance are ok), it might be defective. Replace it (see section 12).

Note: the condition of the motor can be determined by connecting a wire with a fuse directly from the battery to it.

b) if the sound of a running motor is heard, then the vacuum damper may not work. If air comes out of the pipes when starting the engine (bottom vacuum inlet), check the single-acting vacuum valve in the engine compartment on the fire wall to the right of the two heating hoses).

Also check the vacuum hoses on the back of the heating and air conditioning control assembly, make sure they are connected tightly. Further testing of the vacuum flap is outside the scope of this manual.

22. If the mat under the heater radiator is damp or antifreeze vapor or water vapor comes out of the ventilation holes, then the radiator is leaking. Take it off (see section 13) and install a new set.

Visitor comments