Warning: If a steering fastener is loose or lost, replace it immediately with a new one and discard the used one and do not reuse it.

Caution: If the right and left axle drives are removed at the same time, the side gears must be supported so that they do not fall into the housing (only for manual and 3-speed automatic transmissions). For this purpose, wooden pins 23 8 mm are suitable (15/16 inch) in diameter, which are inserted into each side gear. If this has not been done and the gear has fallen, the differential will have to be removed from the gearbox to align the gears. This procedure requires a special puller and an adapter for installing the drive in the hub due to the specific fit of the surfaces of the outer splines of the axle and the inner splines of the hub.

Withdrawal

Note: The information applies to right axle drive vehicles with 3-speed automatic transmission and both drives on manual or 4-speed automatic transmission.

1. Loosen the wheel hub nut, raise the vehicle, and securely place it on stands. Remove the wheel (wheels).

2. Remove the brake caliper and brake disc as described in chapter 9.

3. Unscrew the hub stopper (axle nut) off axis (if you have a 3-speed automatic transmission and you need to remove both axle drives, then start from the right).

Place the lever between the two wheel studs to keep the hub from turning when the nut is loosened.

4. Remove the bolt securing the bracket holding the brake hose to the strut.

5. Unscrew the bolt securing the lower suspension arm to the steering knuckle and separate the arm from the knuckle (see chapter 10).

6. Using a large screwdriver or lever rod, pull out the CV joint assembly located inside the gearbox (see picture) 3-speed automatic and 3-speed manual transmission (only on the right side), unscrew the shaft support bearing from the bracket (see picture). Pull the roller out of the gearbox. Be careful not to damage the body or oil pan. Hang the axle on the wire - do not let it hang over the outer CV joint, otherwise it may damage it.

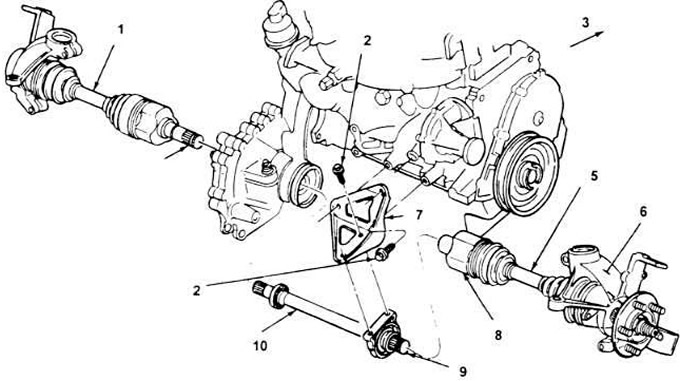

8.6b. Mounting parts for axial drive and tie roller (only manual and 3-speed automatic transmission).

Note: MTX shown. FLC is the same.

1. Knot of the left semiaxis.

2. Bolt.

3. The front of the car.

5. Knot of the right semiaxis.

6. External CV joint.

7. Bracket.

8. Internal SHRUS.

9. Latch ring.

10. Bonding roller.

7. Using a gear puller, remove the axle drive from the hub (see drawing).

8. With the axle drive removed from the hub splines, slide the strut/knuckle assembly out and slide the outer CV joint out of the hub. Pull out the support wire and carefully disconnect the axle drive from the vehicle (or shaft/axial drive assembly) (see picture).

9. If both axle drives are to be removed, insert a tight-fitting wooden pin (15/16 inch diameter) into the side gear of the differential on the right side (not required for 4 speed gearboxes) (see picture); then repeat the operations described in paragraphs 1 to 8 to remove the left axle drive. For the left side gear, also install the support.

Left axle drive on vehicles with 3-speed automatic transmission

10. Remove the right drive, as described above.

11. Using Ford's T81P - 4026 A tool or a narrow screwdriver inserted through the right differential side gear, drive the left drive short shaft out of the left side gear just enough to remove the circlip on the short shaft from the side gear (see picture). Insert wooden pin (15/16 inch diameter) into the right side gear of the differential to prevent it from falling when the left axle drive is removed.

12. When removing the left axle drive from the vehicle, follow the procedures described in paragraphs 7 and 8.

Note: Don't forget to insert the wooden pin into the left side gear.

Installation (both drives)

Note: if both actuators have been removed, install them one at a time by pulling out the wooden pin on each side after the actuator is ready to be installed in the gearbox (only for manual and 3-speed automatic transmissions).

13. Install a new spring ring on the inner splines of the short shaft.

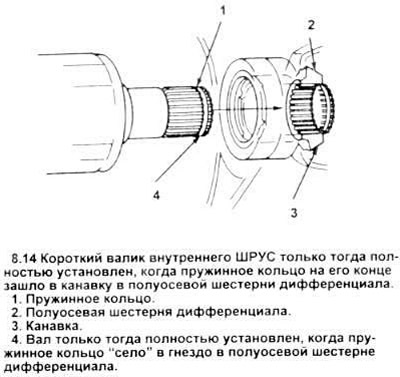

14. Apply a layer of multi-purpose grease to the differential seals and insert a short roller of the inner CV joint or a tie roller (right side only, manual or 3-speed automatic transmission) into the side gear of the differential until the roller is fully installed and the spring ring snaps into place (see picture).

15. Pass a short CV joint through the strut / knuckle assembly and install it in the hub (make sure the slots line up correctly). Manually push the shaft into the hub as far as you can.

16. Bolt tie roll support bearing to bracket and tighten bolts to specification (only manual and 3-speed automatic transmission).

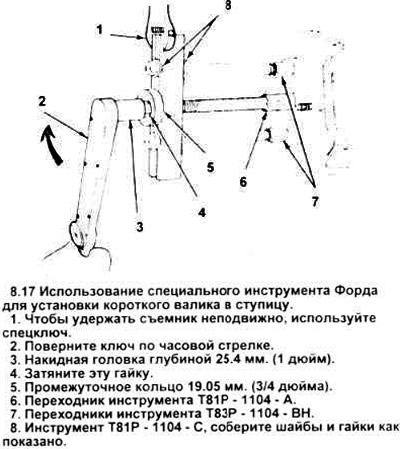

17. Using the Ford tool T81P - 1104 - With adapters T83P - 1104 - BH and T81P - 1104 - A, push the short roller into the hub until. until he falls into place (see picture), then go to paragraph 24.

18. Remove tool and install axle washer and new nut. Tighten the nut to the required torque, and to prevent the hub from turning, place a screwdriver between the two wheel studs.

19. Lower the lower suspension arm down and insert the ball joint stud into the knuckle. Install a new bolt - coupler, tighten it to the desired torque (chapter 10).

20. Install the brake disc and caliper (chapter 9).

21. Install the brake hose support bracket bolt.

22. Hang the wheel, screw on the nuts, lower the car. Tighten the nuts to the required tightening torque.

Visitor comments