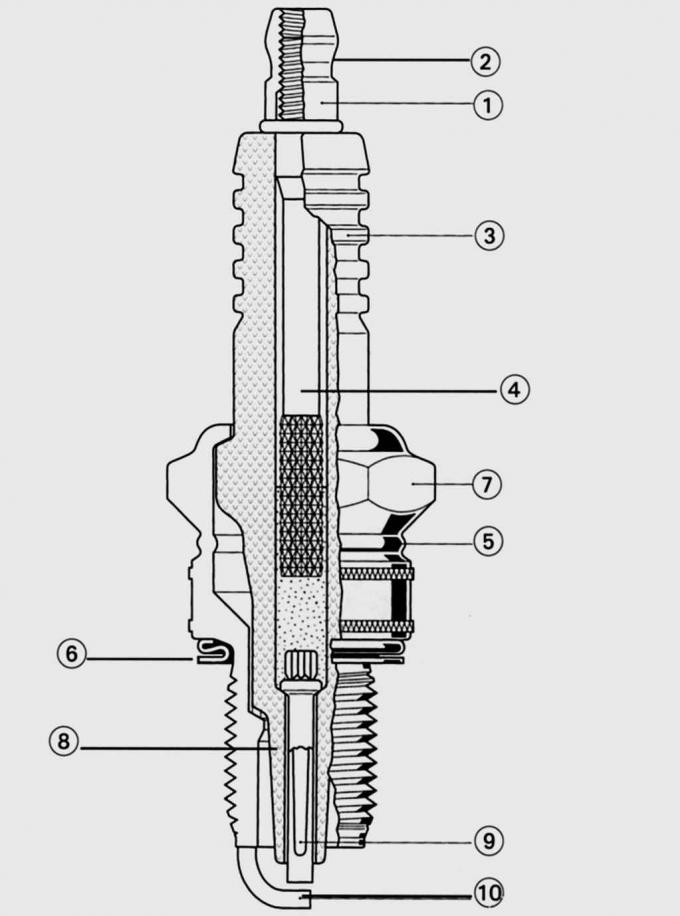

Pic. 9.4. Spark plug: 1 and 2 - threaded lugs for connecting a high-voltage wire; 3 - ceramic insulator with a barrier to exclude surface leakage current; 4 - rod; 5 – the case of a spark plug; 6 - zone of compression and thermal shrinkage; 7 – central electrode; 8 – side electrode; 9 - insulator support; 10 - sealing ring

Spark plug (pic. 9.4) are designed to ignite a small cloud of fine air-fuel mixture with a spark, sufficient to initiate the entire ignition process in the combustion chamber. In this case, a temperature of about 2500°C and a pressure of up to 60 bar are formed. To ensure a stable spark between the spark plug electrodes, the spark plug shaft is surrounded by a ceramic insulator. The central electrode and rod are inserted into an electrically conductive glass melt, which securely fastens these parts and serves as a sealing insulation in the combustion chamber. For a spark to occur, the voltage between the electrodes of the spark plug must rise sharply from zero to the voltage required to form an arc. After a spark discharge occurs, the voltage drops to the level necessary for the spark to propagate, and the air-fuel mixture ignites.

Heat number of the spark plug

The most important parameter characterizing the candle is the temperature regime of its elements, primarily the central electrode and the surface of the insulator skirt. In order for the spark plug to work reliably, after starting the engine, it must quickly reach a temperature that ensures its self-cleaning. This temperature is approximately 400°C. Otherwise, residues of combustion products will settle on the insulator support. At full engine load, the temperature should not exceed 800°C. In addition, the operating conditions for spark plugs are not the same in all engines. Only the glow number determines whether the spark plug and the engine fit together. For example, if you use a spark plug with a very low glow number, the insulator support can become very hot, leading to uncontrolled glow ignition that can even destroy the engine. If, on the other hand, you use a spark plug with a too high glow number, the spark plug will not reach its self-cleaning temperature and the insulator bearing will become dirty.

The most convenient designation of the glow number, at one time adopted by most European firms, in time (in seconds), after which, during tests on a special installation, glow ignition begins. In recent years, most firms have switched to the symbol for the glow number of candles.

Interelectrode gap of spark plugs

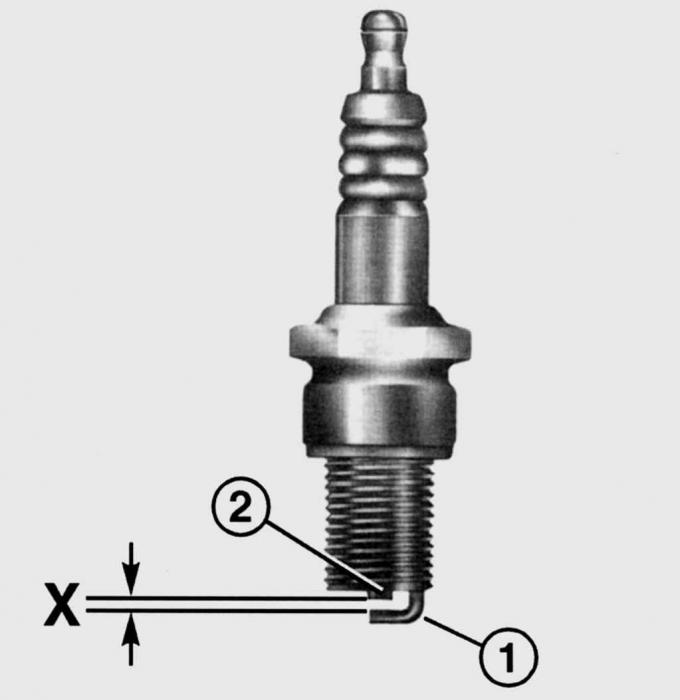

Pic. 9.5. Place of measurement of the interelectrode gap (X) spark plugs between center (2) and side (1) electrodes

In addition to the correct glow number, it is important to know the electrode gap of the spark plug, since if the gap is too large or too small, the size of the spark changes, which leads to a decrease in engine efficiency. The gap must always meet the technical requirements and be 1.3 mm (pic. 9.5).

When the air-fuel mixture is burned, the spark plug electrodes slightly burn. This is facilitated by a spark discharge, which knocks out metal particles from the electrodes, as a result of which the interelectrode gap increases with an increase in the duration of the operation of the spark plugs.

To break down too large an interelectrode gap, a higher voltage is required. It can also lead to misfiring or the engine cannot be started at all. Therefore, it is necessary to check and, if necessary, correct the clearance in a timely manner. The gap is checked with a wire template or a feeler gauge, and its adjustment is done by bending the side electrode.

When replacing spark plugs, be sure to pay attention to the prescribed glow rating and spark plug threads.

Spark plugs recommended for use on Fiesta vehicles are shown in Table. 9.1.

PRACTICAL ADVICE

Precautions when working with the ignition system

Ignition systems are a source of increased danger. Therefore, when working on ignition systems, safety regulations must be observed. It is forbidden to carry out work on the ignition system to people with a pacemaker. In order not to expose yourself to unnecessary danger, entrust the work on the ignition system to a service center. When carrying out maintenance work, extreme care must also be taken.

In no case do not touch the elements of the primary and secondary circuits of the ignition system with the ignition on, which are energized - this is life threatening.

Switch off the ignition before carrying out any work on the ignition system. This rule must also be observed when disconnecting and connecting electrical wires or connecting measuring instruments.

With the ignition on, a slight shaking of the vehicle is enough to cause a high voltage pulse. Therefore, when working in the engine compartment, you endanger your life, in addition, the main components of the ignition system may be damaged.

When welding on a vehicle, disconnect the wires from both battery terminals.

TECHNICAL DICTIONARY

Diagnostics of the engine condition by the appearance of spark plugs

By the appearance of the spark plugs, one can judge the state of the engine, deviations in its operation from optimal parameters. The check must be carried out after warming up the car engine on a high-speed highway. Checking after driving a short distance may lead to erroneous results. During the check, it is necessary to carefully examine the top of the thermal cone of the insulator with the central electrode and the side electrode.

Light gray or brown insulator cone -

indicates that the fuel injection and ignition systems are working properly, ensuring economical operation of the engine.

White color of insulator cone -

indicates that the engine is running on a lean air-fuel mixture or with too much ignition timing (early ignition), which is possible with violations of the adjustment of the ignition timing and the control unit.

Large deposits of soot -

due to the fact that the spark plug does not reach the self-cleaning temperature, i.e. the car is often used for short trips, so the engine does not warm up to normal operating temperature; too rich air-fuel mixture, which increases the content of carbon monoxide.

Oil layer on the insulator cone and electrodes -

appears when piston rings, valve guides or valve stem seals are worn. You may have used motor oil or fuel with additives. Change spark plugs, engine oil and fuel, recheck the condition of the spark plugs.

If the appearance of the spark plugs does not indicate a malfunction in the engine, but its operation is impaired, this may be due to defects in the candles.

Visitor comments