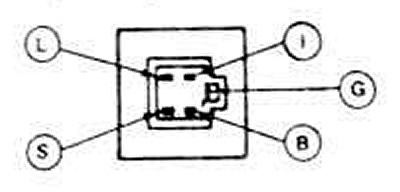

Rear window defroster switch

1. The rear window defroster switch is located on the left trim panel or instrument panel. To check, disconnect the decorative panel from the dashboard, turn it upside down and find the electrical connector for the heater switch

2. According to the instructions (see picture) ground pin G and connect the connecting wire between pins I and B. and between ground and pin L install a 12 volt test light.

18.2. The location of the contacts when checking the rear window defroster switch.

3. Apply power to pin B. The control lamp should not light up.

4. Very quickly turn the switch to the "included". The lamp should light up and remain so after the control link returns to its normal position.

5 The lamp should go out under the following conditions:

- A) if the switch is turned to "included"

- b) if voltage is not applied to the auxiliary (ACC) ignition contact or about 10 minutes have elapsed

6. Apply power to pin S. The control lamp should light up.

7. If the switch fails one of these checks, replace it.

8. To replace, pull out the electrical connector and remove the switch from the air conditioner heater control unit.

9. Install in reverse order.

Defroster wire grill plate

Examination

10. Start the engine and let it idle. Set the control switch to the on position. The indicator lamp should light up.

11. Working inside the car with a voltmeter, connect the wide red-brown strips on the sides of the rear window. The measurement should show 10-12 volts. A lower voltmeter reading indicates a loose ground wire connection on the grounded side of the glass.

12. Find a good ground for the meter's negative lead. The value of the measured voltage should not change.

13. Having grounded the negative wire of the measuring device with a positive contact, touch each grill rod in the middle of its height with the rear window heated:

- A) a value of about 6 volts indicates that everything is in order.

- b) a value of 0 volts indicates a break in the line between the midpoint and the positive side of the grid circuit.

- V) a reading of 12 volts indicates an open circuit between the midpoint and ground.

Repair

Note: breaks in grid lines longer than 25mm (1 inch) not repairable. For shorter breaks use a mesh repair compound and a brown retouch.

14. Work should be carried out at room temperature (16 degrees Celsius (60 degrees Fahrenheit) and higher).

15. Use a glass cleaning solvent to clean the entire area of the screen to be repaired. Remove all foreign matter - dirt, wax, grease, oil, etc. The area to be repaired must be dry and clean.

16. Mark the location of the gap on the outside of the window.

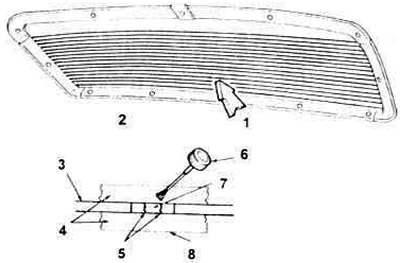

17. Cover the area above and below the tear with tape. The break point should be in the center of the closed area, the distance between the top and bottom tape should not be wider than the thickness of the grid line (see picture).

18.18. Parts for repairing the rear window heater mesh.

1. View A.

2. Using tape, cover its area above and below the gap in the grid. The repaired area should be in the center of the coating, and the gap between the top and bottom tape should not be wider than the grid line.

3. Grid.

4. Ribbon.

5. Place of rupture.

6. Brush for applying the composition.

7. Apply brown touch-up to this place first - if the brown mesh layer is damaged or missing.

8. Close the gap on both sides with tape at least 6.35 mm wide (1/4 inch).

18. If the brown and silver grid lines are broken or missing, then first apply a layer of brown touch-up through the broken area. Two coats may be required to achieve the desired color. Let the retouch dry.

19. Apply three coats of silver grille repair compound. The time between applying layers should be three to five minutes for them to dry. The silver compound plating must cover the tear by at least 14 inches on each side

Note: If the brown mesh layer is not broken or missing, apply only silver compound to the break. Let the composition dry for 5 minutes then remove the frame.

20. Check the mesh repair results from the outside. If the silver layers are visible above or below the grid, then the excess should be removed. This can be done with a razor blade.

Caution: Do not damage the mesh line with a razor blade.

21. The applied coating should dry in the air for a minute, then turn it on for three to five minutes. Normal setting and hardening occurs after about 24 hours. The area to be repaired can then be cleaned with a mild glass cleaner.

Maintenance of the power wire contact

22. Let the rear window of the car warm up to room temperature for half an hour or an hour.

23. Clean the busbar in the repair area.

24. After applying three coats of mesh repair compound, restore the area of the original busbar contact connection. Drying time between coats should be approximately 10 minutes.

25. Tin the busbar with solder in the area where the contact was removed, and work as quickly as possible so as not to heat the glass.

26. Before soldering the contact, preheat the glass in the solder zone with a heating lamp to a temperature of 50-65 degrees Celsius (120-150 degrees Fahrenheit).

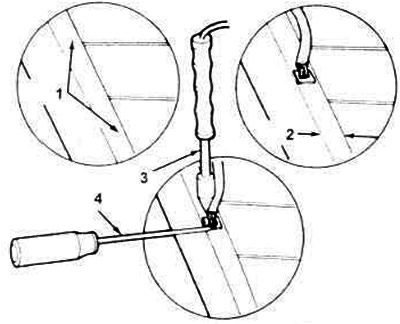

27. Place the contact on the busbar and hold it in place with a screwdriver (see picture).

18.28. Position the contact on the busbar in the tin plated area and hold it in place with a holder or a screwdriver.

1. Collecting tire.

2. Repair area.

3. Soldering iron.

4. Holder.

28. Bring the soldering iron to the base of the contact and hold until the solder melts.

Note: In order not to damage the busbar, and also not to overheat the glass, remove the soldering iron as soon as the solder melts.

29. Start the engine, turn on the heated rear window and leave for five minutes.

Visitor comments