Piston clearances in cylinders must be selected according to the values given in the subsection on pistons.

The surface smoothness of the cylinder should be 3-4 R1. Liners should be selected according to sectional groups of diameters of the crankshaft journals. Inserts into bearing bores must be inserted dry. At the same time, it is necessary to ensure that perfect cleanliness is observed. In order to measure the clearance in the crankshaft bearings, it is necessary to lay the shaft in the bearing holes in the engine housing and do not turn it. Strips are used to measure the gap "Plastigage", which must be placed in the axial direction on each shaft journal. After that, install the bearing caps with shells and use the old bolts to screw in the following way:

- engine 1.1 - torque 88-102 Nm.

- engine 1.4i / 1.6i with a torque of 90-100 Nm.

- diesel engine 1.8

- Stage I - torque 24-30 Nm

- Stage II - turn the bolts 45°

Note: The crankshaft must not be rotated. Otherwise, you will get erroneous measurement results.

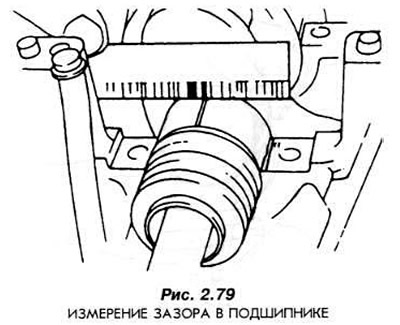

Remove bearing caps and measure strips "Platigage", as shown in Fig. 2.79. If the bearing clearances are correct, the measurements should be within the following limits:

- engine 1.1 - 0.009-0.046 mm.

- 1.4i engine - 0.011-0.058 mm.

- diesel engine 1.8 - 0.015-0.062 mm.

Before installation in the engine housing, the crankshaft must be thoroughly lubricated. Use new bolts to secure the main bearing caps. Be sure to check the ease of rotation of the shaft in the bearings. If you feel uneven rotation at the same time, you will have to loosen the main bearing caps in turn until you find the bearing causing this defect. Determine the cause of the defect and correct it. If, despite the fact that the clearances in the bearings have the correct values, the shaft nevertheless rotates unevenly, the cause of this is most likely the curvature of the interacting parts. In this case, the assistance of specialists from the maintenance workshop, which has special equipment for measuring, is necessary.

Visitor comments