Warning: as a result of wear of the brake linings, dust is formed, which settles on the elements of the brake system. It contains asbestos and is harmful to health. Do not blow it off with compressed air or inhale it. Do not wash off dust with benzine or thinner. The dust is washed off into the sump with the help of a brake system cleaner. Wiping the brakes clean with a damp (solvent impregnated) rags, store the rags and solvent in the sealed, labeled container. If possible, replace parts with asbestos-containing ones.

Note: Since 1990 vehicles have sealed rear wheel bearings which require no maintenance. For replacement procedure, see chapter 10.

1. Remove the rear brake drum assembly (chapter 9).

2. Check that the bearings are well lubricated and that there are no traces of dirt or water in the grease.

3. Using a screwdriver or gasket remover, remove the oil seal from the hub (discard the stuffing box) see figure 23.3.

4. Clean the bearings with solvent and dry them with compressed air.

5. Check bearings for wear, rolling elements, cage and cage for nicks.

6. Some discolouration of the surface of the bearings is normal, but if they are seriously damaged or worn, they should be replaced with new ones.

7. Check the bearing race for wear, overheating, and corrosion. If clips are worn or damaged, use a hammer and punch to remove them (see picture).

8. Install the new bearing races with a piece of pipe and a hammer, being very careful not to damage them or warp them in the bore.

9. Pack the bearing with high temperature EP type multipurpose grease before installing it. Force grease through the gaps between the rollers in the housing (see picture).

10. Add some grease to the hub cavity and the center of the shaft (see picture).

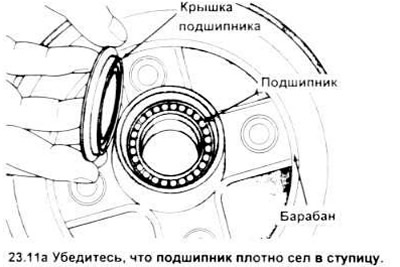

11. Lubricate the outer end of the new oil seal, install the bearing and oil seal in the position with the lip inward (see picture). Achieve tight installation of the oil seal in the hub by tapping it with a hammer through a wooden gasket (see picture). Apply grease to the stuffing box cavity, the flange and the cylindrical surfaces of the shaft.

12. Install hub and drum assembly see chapter 9.

Visitor comments