General description

1. The intake air temperature control system monitors the heating of the air, then adjusts the intake air temperature to the range of 21-41 degrees Celsius (70-105 degrees Fahrenheit) by mixing warm and cold air. This reduces the enrichment of the CFI air/fuel mixture, which in turn reduces emissions and improves vehicle handling.

2. Two fresh air inlets are used - one cold and one hot. The balance between the two is set by intake manifold vacuum control, a vacuum temperature switch and a time delay valve. The vacuum motor regulating the operation of the heat transfer valve of the air cleaner is controlled by a vacuum switch.

3. When the outside temperature is low, the heated air from the exhaust manifold is conducted through the outer hot air duct and into the air cleaner. Thus, the CFI system is provided with warm air, which results in better controllability and faster heating. When the outdoor temperature rises, the heat transfer valve is closed by the vacuum motor, and the air cleaner blows air through the cold air tube. The result is a constant air inlet temperature.

4. Vacuum temperature switch (see picture), mounted on the air cleaner housing, controls the temperature of the intake air heated by the exhaust manifold.

The vacuum temperature switch has a bimetallic disc that self-adjusts to one of two temperature dependent positions. One of the positions of the disc allows the vacuum to enter the motor through the hose, the other blocks it.

5. The operation of the vacuum motor itself is controlled by a cold weather modulator (CWM), mounted side by side in the vacuum temperature switch inside the air cleaner housing (see picture); this modulator sets the motor to one of the graduated positions, the range of which is from "fully open" before "completely close".

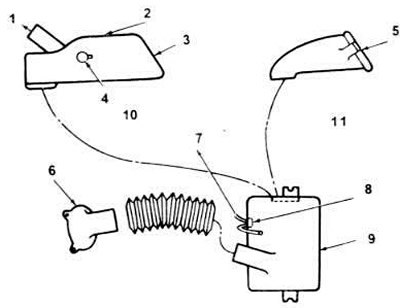

7.5. Location of the cold weather modulator.

1. To the heat pipe.

2 Piping and valve assembly.

3. Fresh air.

4. Vacuum motor.

5. Fresh air.

6. Fuel injection unit.

7. At the vacuum motor (pipeline and valve).

8. Cold weather modulator (CWM) (only for 2.5L CFI).

9. Air cleaner assembly.

10. 2.5L CFI Tauras/Sable.

11. 3.0L EFI Tauras/Sable.

Examination

Note: Make sure the engine is cold before testing.

6. Always check the vacuum source and the integrity of the hoses between the source and the vacuum motor before proceeding with the proposed testing.

7. Apply the parking brake, block the wheels.

8. Disconnect but do not remove the air cleaner housing and element (see chapter 4).

9. Rotate the air cleaner housing so. so that the vacuum motor door is visible. The door must be open.

Make sure it is not stuck open or closed by trying to move it by hand. If there is rust, the door should be cleaned and oiled. If the door still does not function normally after servicing, replace it.

10. If everything is in order with the door, but the vacuum motor still does not function normally, carefully inspect the hose leading to it - it may be leaking. Check vacuum source including bimetal and time delay valve. If there is no leakage, replace the vacuum motor (see paragraph 26).

11. Start the engine. If the pipeline damper has moved or is shifting towards the position "heat" (shutting off fresh air), go to paragraph 15.

12. If the damper remains in position "heating on" (shutting off warm air), block the output from the bimetal sensor with your finger. The pipeline damper should quickly move to the position "heat". If this does not happen, turn off the engine and replace the vacuum motor (see paragraph 26). Carry out the operations indicated in this paragraph on the new motor.

13. With the engine off, cool the bimetal sensor and cold weather modulator by blowing compressed air over them.

14. Start the engine again. The piping door should move into position "heat". If it does not, or if it is only partially displaced, replace the TVS (see paragraph 18).

15. Start and warm up the engine quickly (less than 15 sec). The piping door should move to the position "heat".

16. Turn off the engine, watch the door. She must stay in position "heat" at least two minutes.

17. If this does not happen, replace the CWM (see paragraph 23) and repeat the operations of this paragraph again after the CWM and the bimetal sensor have cooled down.

Replacing elements

Vacuum temperature switch (TVS)

18. Tag and disconnect both vacuum hoses from the TVS assembly (one goes from the vacuum source to the manifold and the other goes to the vacuum motor under the air cleaner housing).

19. Remove the air cleaner housing cover (see chapter 1 or 4 if necessary).

20. Using a screwdriver, remove the TVS clip.

21. Remove TVS.

22. Install in reverse order.

Cold weather modulator

23. Disconnect the air cleaner housing assembly (see chapters 1 and 4) and turn it over.

24. Locate the CWM, disconnect both vacuum hoses and remove the modulator.

25. Install in reverse order.

Vacuum motor

26. Disconnect the air cleaner housing assembly (see chapters 1 and 4) and turn it over.

27. Find a vacuum motor.

28. Disconnect the vacuum hose and drill out the motor mounting rivet.

29. Remove the motor.

30. Install in reverse order.

Visitor comments