General description

1. The system is designed to prevent hydrocarbons from entering the atmosphere by trapping and concentrating fuel vapors from the carburetor gas tank or fuel injection system.

2. Serviceable system components include a charcoal tank and connecting pipes between the gas tank, tank filler cap and fuel injection system (see picture).

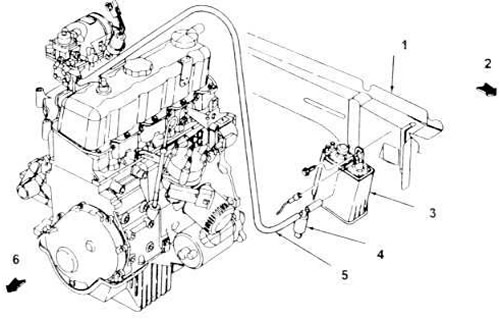

5.2, a. Typical Collection Vessel Ventilation System (four-cylinder engine).

1. Left lower frame rail.

2. The front of the car.

3. Capacity.

4. Cleaning solenoid.

5. Withdrawal to the PCV pipeline.

6. Front of the engine.

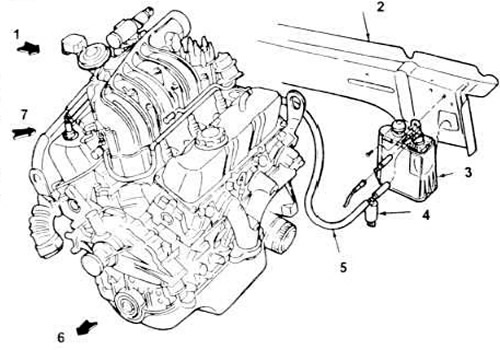

5.2b. Typical ventilation system for a vapor collection tank (3.0LV6 - 3.8LV6 engine shown similarly).

1. The front of the car.

2. Left lower frame rail.

3. Capacity.

4. Cleaning solenoid.

5. The conductive hose runs over the transmission and into the upper PCV valve inlet on the right timing cover.

6. Front of the engine.

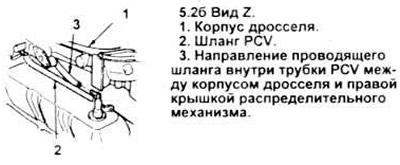

7. View Z.

3. Vapors trapped in the gas tank pass through the valve at the top of the tank. Vapors leave the valve through the pipeline and are brought to a container with coal located between the arch of the left front wheel and the front bumper, where they accumulate until the next time the engine is turned on.

4. The container outlet is connected to the body cleaning solenoid, which is activated by an electrical signal (see picture); this solenoid is in turn connected to the air cleaner housing Normally the housing cleaning solenoid is in the closed position. When the engine is turned on, the solenoid receives a signal from the ECA, and it allows the intake vacuum to open the pipeline between the tank and the air cleaner housing, as a result, the vacuum removes the fuel vapors stored in the tank through the air cleaner to the engine, where they burn out.

Examination

Coal capacity

5. There are no moving parts in the tank, therefore, there is nothing to wear out. Check for loose, cracked, broken, or missing tips, and inspect the container itself for cracks or other damage. Replace damaged container (see paragraph 9).

Tank cleaning solenoid valve

6. Remove valve (see paragraph 13).

7. With the valve de-energized, apply a vacuum source of 5 inches of mercury to the inlet (see figure 5.4). The valve must not let air through. If it skips, replace it.

8. Using additional wires, apply 9-14 volts to the valve electrical terminals. The valve should open and allow air to pass through. Otherwise, replace the valve.

Replacing nodes

Coal capacity

9. Locate the container in the engine compartment.

10. Find above the container and unscrew its only fixing bolt (see picture).

11. Lower canister, disconnect hose from purge valve or purge solenoid valve, remove canister.

12. Install in reverse order.

All other elements

13. Based on the vacuum supply hoses, the valve diagrams in this section, and the VECI label on your vehicle, locate the item that needs to be replaced.

Visitor comments