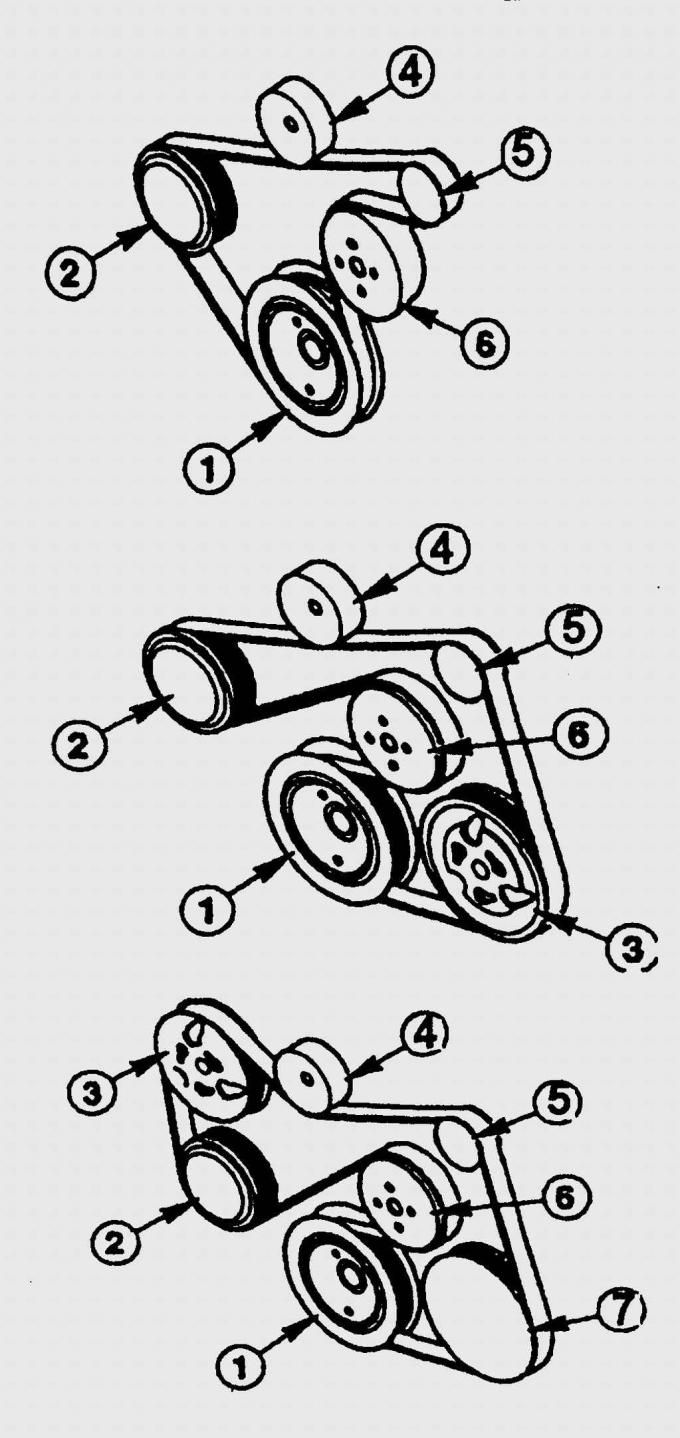

Pic. 4.15. The location of the poly V-belt 6K-Poly-V on the pulleys of the Zetec-SE engine, depending on the equipment of the vehicle: 1 - crankshaft pulley; 2 - a pulley of a hydraulic belt tensioner; 3 – a pulley of the pump of the amplifier of a steering; 4 - guide roller; 5 - generator pulley; 6 - water pump pulley; 7 - air conditioner pulley

Auxiliary units (generator, water pump, etc.) Fiesta cars are driven by a poly V-belt, in the new OHC engines this task is performed by the 6K-Poly-V belt. Ford mainly uses V-ribbed belts, which move particularly flexibly along the radii of the belt pulleys. A hydraulic device adjusts the belt tension.

If you have a vehicle with air conditioning or power steering, the belt dimensions are different than those on the base model. Be sure to carry the appropriate replacement V-ribbed belt in your trunk.

V-ribbed belt pretensioning

V-belts only do their job well if they have the right amount of pre-tension: they should be tight, but not too tight. It is normal for the belt to deflect between 3 and 5 mm when pressing the center of the belt leg between the two pulleys. Tight belts will eventually destroy the bearings of the generator, water pump (depending on engine type) and air conditioning compressor. In addition, taut belts stretch and can break later. On the contrary, sagging V-belts slip - this is noticeable by the creaking sounds. This is most detrimental to the alternator, as it does not produce enough charging current, which leads to a large load on the battery when traveling short distances and when starting a cold engine. The V-ribbed belt is also damaged, its sides burn, and premature wear occurs. In extreme cases, slipping V-ribbed belts can lead to overheating of the engine and severe damage to parts and assemblies (jamming of the pistons, burning of the cylinder head gasket). Although the Fiesta's engine automatically adjusts the tension of the V-ribbed belt, check its condition occasionally.

SEQUENCE OF WORK

1. Check the condition of the belt.

2. Turn the crankshaft several times by hand. Only in this way can you reliably check the condition of the V-ribbed belt along its entire length. Often poly-V-belts have one, but a very deep crack. And if this crack, unfortunately, is located on the belt pulley during inspection, you will not notice it, which in the end can lead to serious consequences, despite the inspection carried out.

3. If you find the following damage on the V-ribbed belt, replace it immediately:

- uneven wear marks on the sides of the belt;

– porous, frayed belt edges or surfaces;

- cracks.

PRACTICAL ADVICE

Installing the V-ribbed belt

Never use a screwdriver to put a new belt on the pulleys. Otherwise there will be «programmed» subsequent damage to the underside of the belt where you inserted the screwdriver. After installing a used belt, the engine should run for approximately 3 minutes (if the belt is new - 10 minutes), then recheck the preload. Increase the engine speed slightly before turning off the engine. After about 1000 km of run, recheck the belt tension (deflection should be 3–5 mm).

Installing the V-ribbed belt

SEQUENCE OF WORK

1. Turn away a fixing bolt on a tension bracket of the generator.

2. Loosen the bolt on the pivot bearing.

3. Turn away the generator towards the engine.

4. Replace the old V-ribbed belt with a new belt.

5. Installation is carried out in the reverse order of removal.

PRACTICAL ADVICE

If the belt is broken

If the red battery charge warning lamp lights up while driving, this indicates a broken V-ribbed belt. In doing so, you will notice a hard hit on the wheel arch or front wall in the engine compartment. In no case should you continue to move further, as the water pump is driven by the belt and the circulation of the coolant stops, and the remaining liquid in the cylinder block boils quickly, you risk severe engine damage. Therefore, immediately replace the broken belt with a spare one or have the vehicle towed to the nearest workshop.

TECHNICAL DICTIONARY

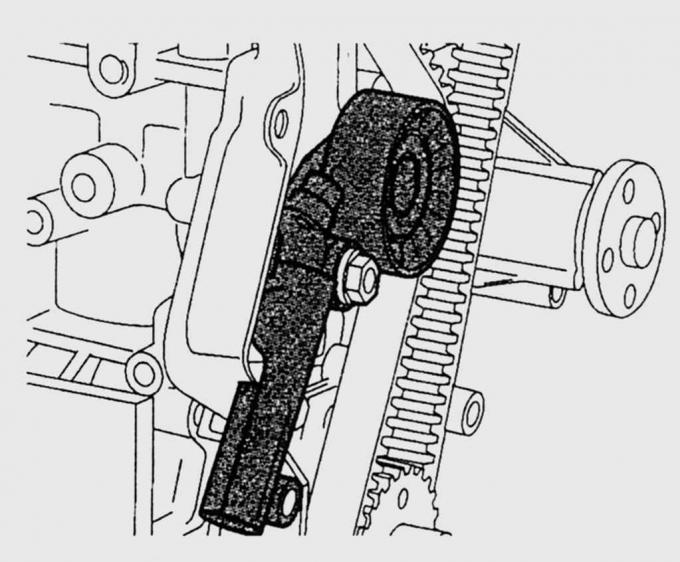

Pic. 4.16. The location of the hydraulic device for tensioning the toothed belt on Fiesta ONC / DOHC engines

Toothed belt and camshaft

The timing mechanism of the Zetec-SE and 1.8D Endura-DE engines is driven by a toothed belt from the crankshaft pulley. Timing belts are maintenance-free, made of artificial material and reinforced with steel wire, tensioned by a hydraulic device. Ford recommends replacing the toothed belt every 150,000 km of the vehicle. Since the valve timing may be disturbed when replacing the belt, the replacement should be carried out at a Ford service center. Specialists will also check the operability of the tensioner and, if necessary, replace it.

Visitor comments