New four-cylinder Zetec-SE engine installed in Fiesta since 1996

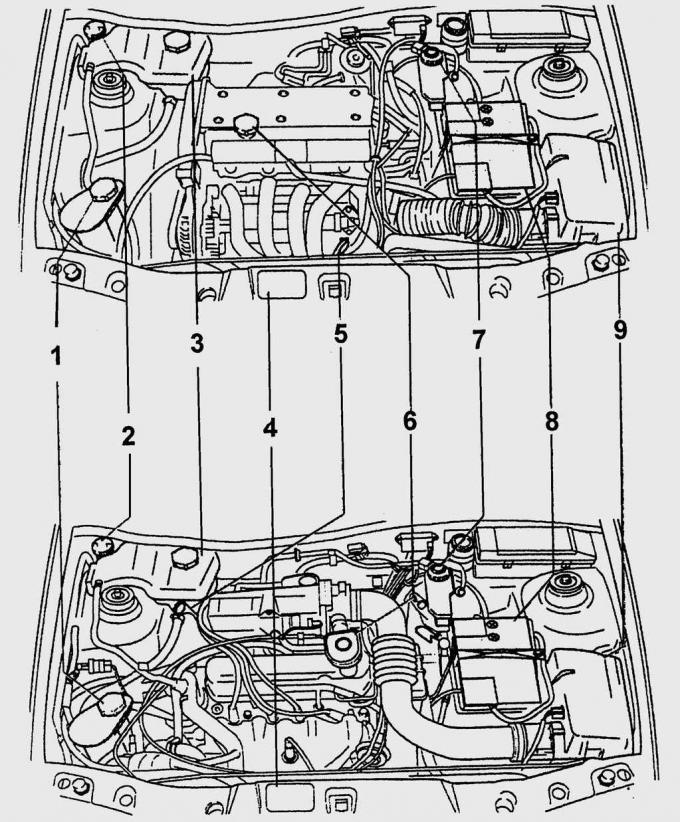

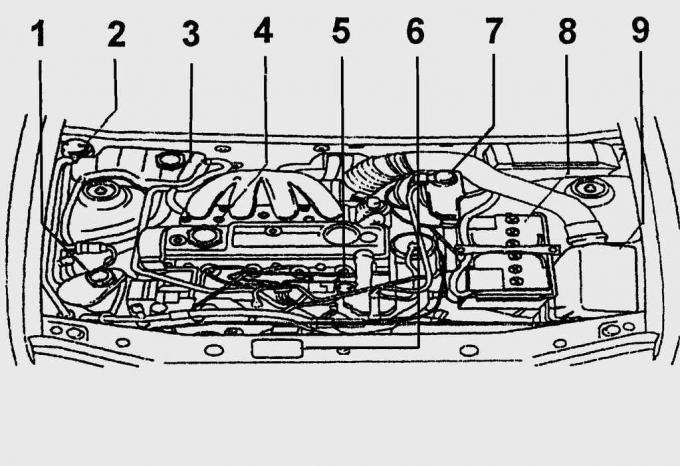

Pic. 4.1. Engine compartments with Zetec-SE 1.25 and 1.4L engines (up) and Endura-E 1.3L (at the bottom): 1 – a reservoir of the hydraulic amplifier of a steering; 2 - washer reservoir; 3 - expansion tank of the cooling system; 4 - a plate with the technical data of the car; 5 - engine oil level indicator; 6 - oil filler neck; 7 - reservoir for brake fluid; 8 - storage battery; 9 - air filter

It is undeniable that Zetec-SE DOHC engines with a displacement of 1.25 liters (55 kW / 75 hp) and, accordingly, 1.4 l (66 kW / 90 hp) have been the technical excellence of the Fiesta series since 1996. In the engine compartment, the engines are installed with an inclination of 12°back. By the way, these are the first transversely mounted Ford engines with injection elements located on the front side of the cylinder head. This solution significantly improves access to all elements of the injection system during repair and maintenance. The angle of inclination is of great importance, since with «turn» cylinder heads, the exhaust system is no longer in the cooling air stream, but «hiding» behind the engine. This slope provides plenty of room between the engine and the front baffle to reduce heat transfer to the engine from the exhaust manifold and catalytic converter. Engine compartments with Zetec-SE 1.25 and 1.4L and Endura-E 1.3L engines are shown in fig. 4.1.

Technical Cooperation with Yamaha Corporation

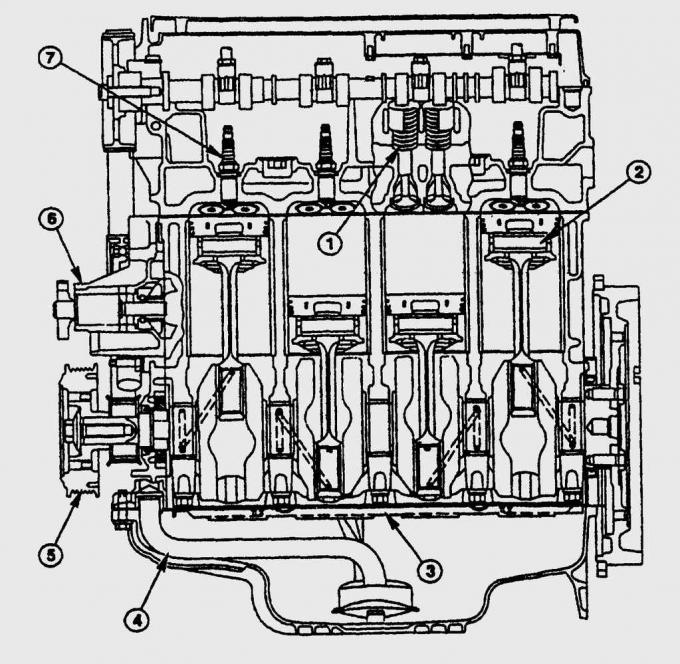

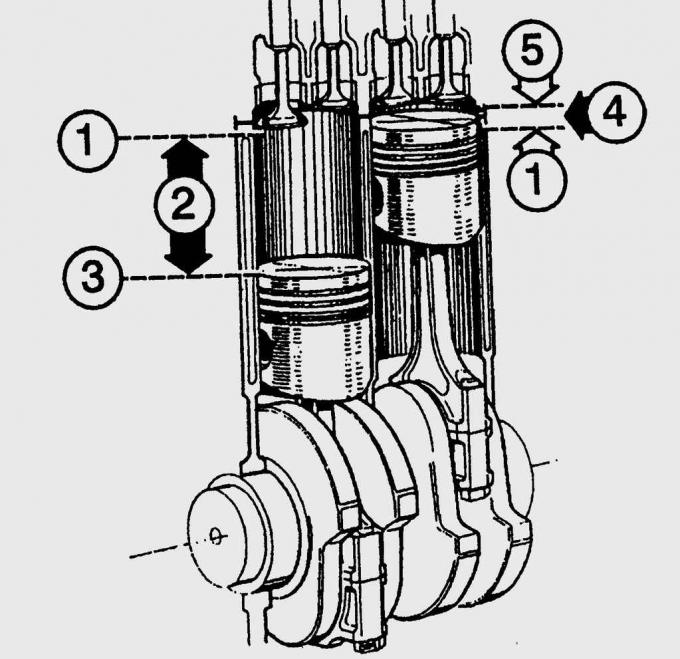

Pic. 4.2. Section of the Zetec-SE engine: 1 - valve mechanism; 2 - piston; 3 - oil baffle plate; 4 - oil intake tube; 5 – vibration damper; 6 - water pump; 7 - spark plug

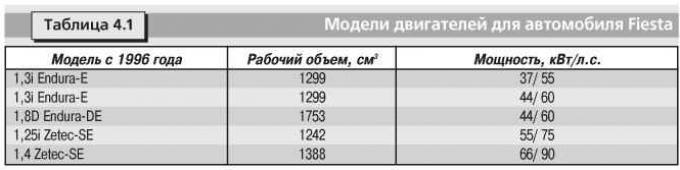

Both Zetec-SE engines, ranging in displacement from 1.1 to 1.7 liters, are the forerunners of a series of engines developed by Ford in collaboration with Yamaha Corporation. A feature of the compact four-cylinder engines is the installation of four valves per cylinder and electronic control, as well as the use of a Ford engine control unit (EEC-V) new generation. This made it possible to implement precise control of the air-fuel mixture and ignition, as well as improve the diagnosis and regulation of the idle speed. In practice, these solutions have led to a reduction in the emission of harmful substances with exhaust gases and a more uniform combustion process at any load. A further innovation of Zetec engines is the very high degree of filling of the cylinders and, as a result, a high power density of 44.3 kW/l. This becomes even more significant when considering the effective mean pressure, which is an indicator for efficiency in the form of a specific torque. The average pressure of all Zetec-SE engines is much higher than other Ford engines in this class. The section and front view of the Zetec-SE engine are shown in fig. 4.2 and 4.3.

Pic. 4.3. Front view of the Zetec-SE engine: 1 - exhaust camshaft; 2 – a camshaft of inlet valves; 3 - inlet channel; 4 - oil intake tube; 5 - crankshaft; 6 - outlet channel; 7 - hydraulic tensioner of the toothed belt; 8 – a pulley of a camshaft of final valves; 9 – a pulley of a camshaft of inlet valves

Cylinder block and cylinder head

The cylinder block and cylinder head, as well as the bodies of most additional components and assemblies, are made of a special aluminum alloy. The valve cover is made of magnesium and the suction pipe is made of plastic. Engines have two overhead camshafts (DOHC) and are equipped with a multi-valve mechanism - four valves per cylinder. A number of design solutions made the engine quieter, reduced its vibration and emissions of harmful substances with exhaust gases, and minimized maintenance time. Thanks to the hydraulic valve clearance compensation, the valve clearances are only checked by a workshop every 150,000 km. Valve clearance on a cold engine is 0.17–0.23 mm for intake and 0.27–0.33 mm for exhaust valves. The spark plugs are replaced every 45,000 km, the engine oil and oil filter are replaced after 15,000 km of the car's run.

Engine Power 1.25i Zetec-SE 1.25L displacement (55 kW / 75 hp), as in a conventional 1.4 liter engine

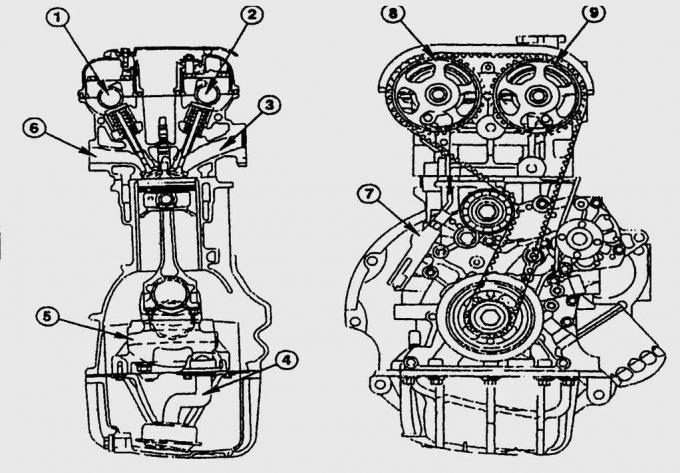

The new 1.25L 16-valve engine delivers the same power as a conventional 1.4L engine. At the same time, in his concept, the least attention is paid to such absolute data as dynamism and fuel consumption. With an exceptionally smooth torque curve, the engine does not constantly require the highest speed of the crankshaft, but already feels great at 2000 min-1 (pic. 4.4). The 1.25i engine already reaches its maximum torque of 110 Nm at 4000 min-1. The highest power of 55 kW / 75 hp it develops at 5200 min-1. This is quite enough to feel free in normal traffic flow (acceleration from 0 to 100 km/h in 12.7 s) and on motorways to accelerate the Fiesta to 170 km/h. Fuel consumption is modest - the 1.25i engine consumes only 6.4 liters of gasoline per 100 kilometers.

Pic. 4.4. Zetec engine power diagram 1.25 l, 55 kW (75 HP)

Combination of Zetec-SE engine and CTX automatic transmission

Ford combines a Zetec engine with a CTX continuously variable automatic transmission. Although the 1.25i engine's dynamism is lost in this combination with an automatic transmission, the Fiesta still delivers high performance. It accelerates from zero to 100 km/h in 15.6 seconds, and the Fiesta CTX reaches a top speed of 160 km/h. All this happens at a high level of comfort without shifting and with relatively low fuel consumption - 6.7 liters of gasoline per 100 kilometers.

Zetec-SE 1.4i engine (66 kW / 90 hp)

With a fuel consumption of 6.9 liters per 100 kilometers, the Zetec-SE 1.4i engine can compete with most conventional 1.6 liter engines. It also ranks first in terms of power figures: 66 kW / 90 hp. at a crankshaft speed of 5600 rpm-1 is a high figure for any temperamental Fiesta driver. The 1.4i engine accelerates the car from standstill to 100 km/h in 10.8 seconds, and the car reaches a top speed of 180 km/h. The most powerful Zetec-SE engine of the Fiesta with a displacement of 1.4 liters already provides sufficient thrust at 2000 min-1. The 1.4i engine reaches its maximum torque of 125 Nm at 4500 min-1.

Endura-E engines (37 kW/ 50 HP, 44 kW/ 60 HP) since 1996 - serial equipment of cars

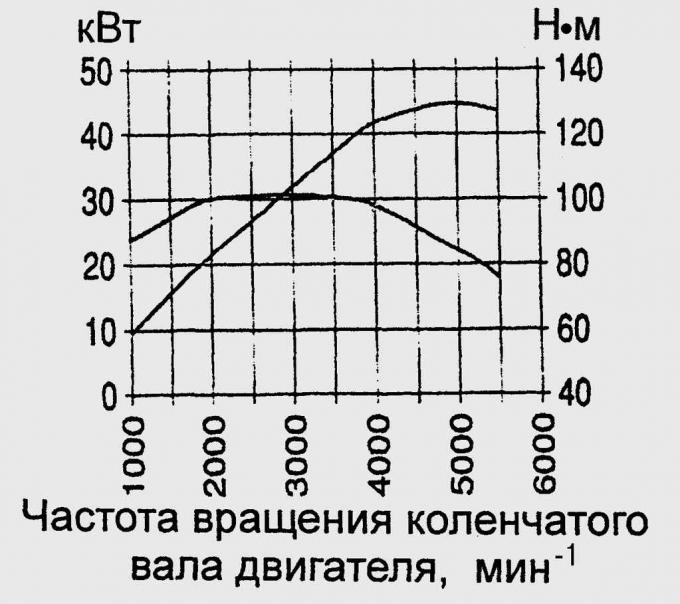

As an alternative to both Zetec-SE engines, Ford is offering the Fiesta with two other gasoline engines. The engines are 1.3L and internally designated Endura-E. The basic version has a power of 37 kW/50 hp. at 4500 min-1 (pic. 4.5). The more powerful Endura-E duo engine delivers 44kW/60hp. at 5000 min-1. Endura-E engines are extensively modified versions of the OHV-HCS injection engine that has been running flawlessly in the Fiesta for many years. But in comparison with the repeatedly proven «original» Ford has significantly improved Endura-E engines in terms of ride and emissions.

Pic. 4.5. Endura-E 44kW Engine Power Chart (60 HP)

Suction nozzle made of plastic

To effectively improve efficiency, Ford has developed new cylinder heads for Endura-E engines with swirl ports and compact combustion chambers. On the suction side, plastic suction pipes with smooth inner surfaces are installed, which have better thermal insulation. This completely eliminated the stick-slip symptom found in older OHV-HCS engines when running on a lean air-fuel mixture. In this case, the air-fuel mixture passes through the plastic pipe without condensation, and the behavior of the engine during warm starts is also improved due to reduced heat loss.

Sequential fuel injection is standard on Endura-E engines

Further new to all Endura-E engines are sequential fuel injection, a state-of-the-art EEC-V engine control unit, a near-engine catalytic converter, an aluminum cast oil sump, and a new engine mount.

In general, all of the changes to the Endura-E engines have resulted in significantly improved engine performance and a noticeable reduction in cabin noise levels.

Pic. 4.6. Engine compartment with Endura-DE 1.8 engine: 1 – hydraulic power steering reservoir; 2 - washer tank; 3 - expansion tank of the cooling system; 4 - oil filler neck; 5 - engine oil level indicator; 6 - a plate with the technical data of the car; 7 - reservoir for brake fluid; 8 - storage battery; 9 - air filter

1.8L ONS diesel engine (44 kW/ 60 HP) with EEC-V electronics and oxidation catalytic converter - standard equipment since 1996

The new Endura-DE engine is a further development of the 1.8L diesel engine (44 kW/ 60 HP at 4800 min-1).

Pic. 4.7. Endura-DE 44kW Engine Power Chart (60 HP)

It differs from all Fiesta car engines in its specifically low fuel consumption. Its fundamental modifications of parts correspond to the volume of gasoline engines. Specific changes to the Endura-DE engine - it was developed based on the latest EU emission regulations - are limited to new injection elements, a differently calibrated and controlled EEC-V unit, a distributor-injection pump, and an oxidation catalytic converter located near the engine, which is controlled by the electronic unit in the Fiesta. Since 1996, cold start has been improved by glow plugs (EZD 35), which also at outside temperatures down to -15°C limit the pre-glow time to 4 s. The power diagram of the Endura-DE engine is shown in fig. 4.7.

Fiesta Diesel Noise Reduction Solutions

A modified engine mount, a separate air filter, a new exhaust system and additional noise reduction solutions have made the Fiesta diesel engine quieter than its predecessors. The 1753cc3 Endura-DE engine delivers adequate power in the upper rev range and tractive effort in the mid-range revs. The torque curve of the swirl chamber diesel engine is exceptionally flat – in practice this translates into good traction. The Endura-DE engine peaks at 105 Nm of torque at 2500 min-1 and almost 70% of that is consistently present above the overall power curve. The diesel engine accelerates the car from standstill to 100 km/h in 17.6 seconds, while at 155 km/h the fuel pump regulator limits the top speed. In typical diesel driving – as much as possible at low engine speeds – the maximum diesel fuel consumption is 5.7 liters.

Choosing the best engine repair option - in the workshop or on your own

Despite its robust design, Fiesta engines require repair and adjustment work. This work must be carried out in a workshop. Skilled craftsmen have the necessary specialized knowledge and experience and usually have the right tools to complete most repairs.

For example, an improperly replaced toothed belt can cause serious damage to pistons and valves. A qualified repair to replace the cylinder head gasket and valves will save you at least repairing damage to the engine bearings. If you are not completely sure that you can repair the engine on your own, for the sake of your own wallet, forget about doing it yourself. You are left with only a series of inspection and maintenance work that you can do yourself.

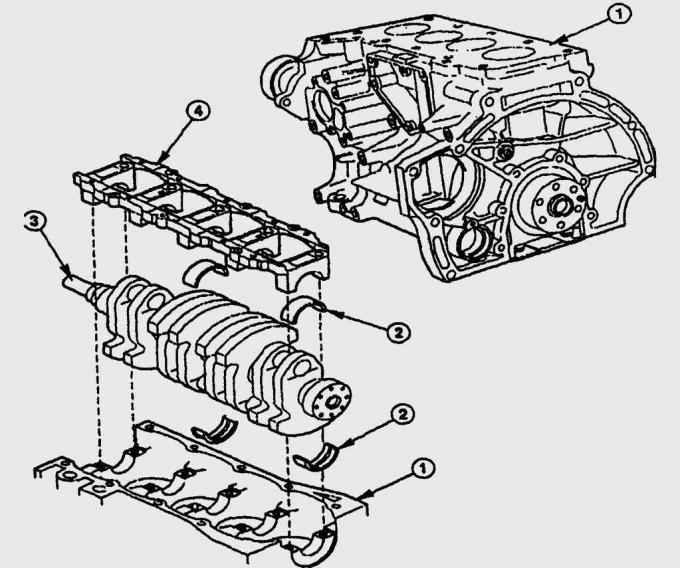

Fiesta engine models

Models of engines for the Fiesta car are given in table. 4.1.

TECHNICAL DICTIONARY

Engine elements

Cylinder block.

Pic. 4.8. The block of cylinders of the Zetec-SE engine of the Fiesta car: 1 – the block of cylinders; 2 – liners of radical bearings; 3 - crankshaft with eight counterweights and five main journals; 4 - jumper with caps for main bearings

It has a crank mechanism and elements of the engine lubrication system. On the periphery of the cylinder block, additional units and components are installed, such as a generator, starter and ignition system. The cylinder blocks of both Zetec engines are made of a light alloy of aluminum and silicon, while gray cast iron is used in the manufacture of Endura engines. Robust molded sidewalls and web with main bearing caps make the block especially torsion resistant (pic. 4.8).

Cylinder head.

In modern engines, the cylinder head is made of an alloy of light metals and is mounted on top of the cylinder block. The head has suction and exhaust channels, cooling and lubrication channels, valve seats, valve train bearings, as well as threaded holes for spark plugs or fuel injectors and a combustion chamber. The cylinder head gasket is located between the cylinder block and the head, it protects both parts from getting into them from the outside and from the inside of oil, coolant and air.

Cylinders.

They move the pistons between the bottom dead center «UT» and top dead center «FROM». The diameters of the working surfaces of the cylinders exactly correspond to the diameters of the pistons, and their surfaces are additionally honed. Cylinders are cooled through cooling channels or with wet working sleeves directly with coolant.

Pistons.

They move in cylinders and transfer the pressure of the combustion products through the connecting rods to the crankshaft. They are made of a particularly light and heat-resistant alloy. Their main elements are the piston crown, piston ring grooves, piston pin bore and piston skirt. The piston pin connects the piston to the connecting rod. Top compression piston rings seal the combustion chamber from the crank mechanism. The lower oil scraper ring removes excess oil from the cylinder wall into the oil sump.

Connecting rods.

The pistons are connected to the crankshaft and consist of a hole in the upper head into which the piston pin is pressed, a connecting rod rod, a lower connecting rod head and a lower head cover that covers the crankshaft journal.

Crankshaft.

Together with the connecting rods, it converts the reciprocating motion of the piston into rotational motion in order to obtain torque. The crankshaft consists of main journals that rotate in the main bearings of the cylinder block, and two counterweights for each cylinder, which are connected by connecting rod journals. Fiesta engine crankshafts have five main bearings and four 90°offset connecting rod bearings. All bearings are equipped with replaceable bushings, which are replaced when worn.

Valves.

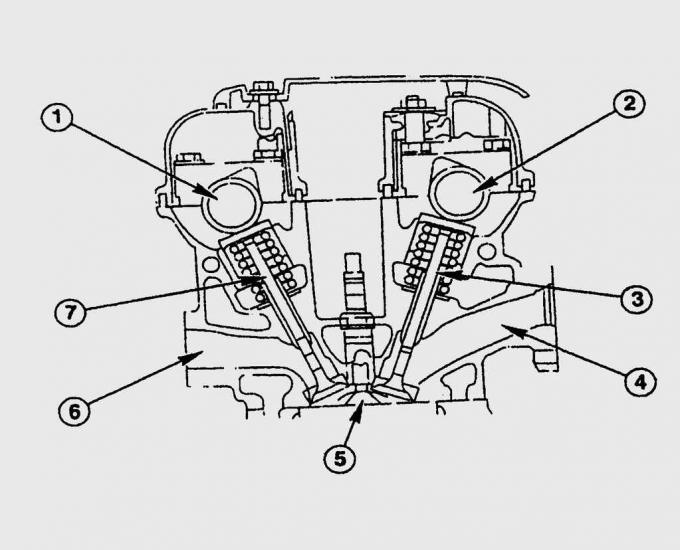

Pic. 4.9. The valve mechanism of the OHC / DOHC engines of Fiesta cars, driven by a toothed belt: 1 - exhaust camshaft; 2 – a camshaft of inlet valves; 3 - inlet valve; 4 - inlet channel; 5 - spherical combustion chamber; 6 - outlet channel; 7 - exhaust valve

Controls the change of cycles in four-stroke engines (suction, compression, combustion, exhaust). In Endura engines, the valves are located in a row in the cylinder head, while in Zetec engines, the valves are located on the side (radial arrangement). The moving parts in the cylinder head form the valve train.

distribution shafts.

Open and close the valves depending on the engine speed and the position of the pistons at precisely set intervals.

TECHNICAL DICTIONARY

How a four-stroke engine works:

Inlet (1st measure).

The piston moves from top dead center «FROM» to bottom dead center «UT». The intake valve opens and the air-fuel mixture is sucked into the cylinder.

Compression (2nd measure).

Piston moves from bottom dead center «UT» to top dead center «FROM» and compresses the sucked in fresh air-fuel mixture. The intake and exhaust valves are closed.

working stroke (3rd measure).

Before the piston approaches top dead center, the compressed fresh air-fuel mixture is ignited by a spark generated between the spark plug electrodes. The mixture burns very quickly, and due to a sharp increase in pressure in the combustion chamber, the piston begins to move down to bottom dead center «UT». When the piston moves in the power stroke, it transfers energy to the crankshaft and converts it into rotational motion.

Release (4th measure).

The inertial mass of the flywheel again moves the piston away from bottom dead center «UT» towards top dead center «FROM». Since the exhaust valve is already open, the exhaust gases are released into the exhaust system. Together, the four cycles form a gas mixture change in a four-stroke engine. The diesel engine works on the same principle. In the intake stroke, it sucks in only clean air, compresses it to a greater extent, so that at the end of the compression stroke, the diesel fuel injected into the cylinder spontaneously ignites from hot air without an additional spark (ignition sparks). The remaining change of the gas mixture is completely identical to the gasoline engine.

The working volume of the cylinder.

This is the distance that the pistons travel in their movement from bottom dead center «UT» to top dead center «FROM», times the area of the piston. The combustion chamber has no effect on the cylinder displacement. The working volume of the cylinder and the combustion chamber form the volume of the cylinder.

Compression ratio.

The dimensions of the combustion chamber do not directly affect the compression ratio. The compression ratio means how much fresh air should be at 100% filling (wide open throttle) in the combustion chamber. Endura engines have a compression ratio of 9.5:1, while Endura-DE engines have a compression ratio of 21.5:1. The Zetec 1.25i engine runs at a compression ratio of 10:1, while the Zetec 1.4i engine runs at 10.3:1.

Turning the crankshaft of the engine

To perform certain operations, the engine crankshaft must be rotated and set to a certain position. In a four-stroke engine, the piston passes through top dead center twice during four working cycles: the first time when the air-fuel mixture that has entered the cylinders is ignited and the second time after the exhaust gases are released, with the subsequent intake of the mixture starting. Usually, during various adjustment work, it is required to set the piston of the first cylinder to top dead center on the compression stroke.

Pic. 4.10. The displacement of a cylinder is the distance (2), which the pistons pass from top dead center (1) to bottom dead center (3), times the area of the piston. In the volume between the piston located at top dead center «FROM» (1), and the concavity of the cylinder head (5) located combustion chamber (4)

Piston position at top dead center «FROM» the first cylinder is shown on the right side in fig. 4.10. When the piston of the first cylinder (on the right side of the road) is exactly at top dead center, the valves of the fourth cylinder overlap (exhaust valve closes, intake valve begins to open). The valves of the first cylinder are completely closed. In most engines with an ignition distributor, the position of the piston at top dead center «FROM» The piston of the first cylinder is determined based on the position of the ignition distributor rotor and the mark on the flywheel, which must be aligned with the fixed pointer.

SEQUENCE OF WORK

1. Raise the front wheel as for changing it and shift into 5th gear. When turning the raised wheel forward, the engine crankshaft will also rotate. Turning the crankshaft will be easier if you first turn out the spark plugs. If you are unable to raise and secure the vehicle, shift into 5th gear and gently push the vehicle forward until cylinder #1 is at top dead center «FROM».

2. Without help, you can turn the crankshaft using the socket head mounted on the crankshaft pulley bolt. The crankshaft rotates better if you press the toothed belt at the same time. With this method, always make sure that the crankshaft rotates only clockwise.

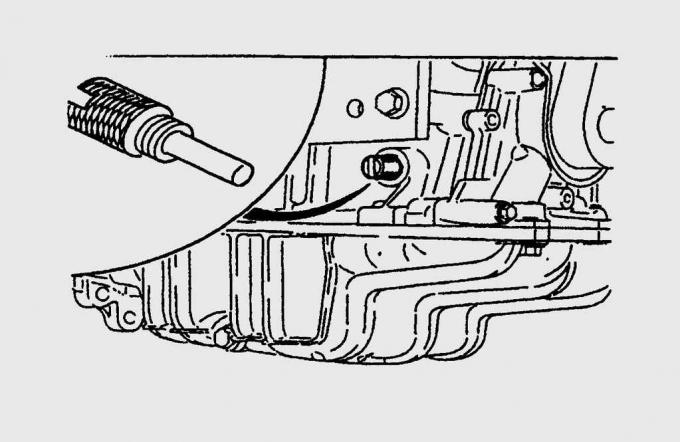

Pic. 4.11. Position of the dowel pin (special tool 21-210) to set the crankshaft of the engine to the position of the top dead center of the piston of the first cylinder

Top dead center «FROM» crankshaft is determined only by a special tool. In Ford workshops, a dowel pin is screwed into the side of the cylinder block for this purpose «FROM» (special tool 21-210) (pic. 4.11). The crankshaft rotates until the crankshaft counterweight is firmly against the dowel pin.

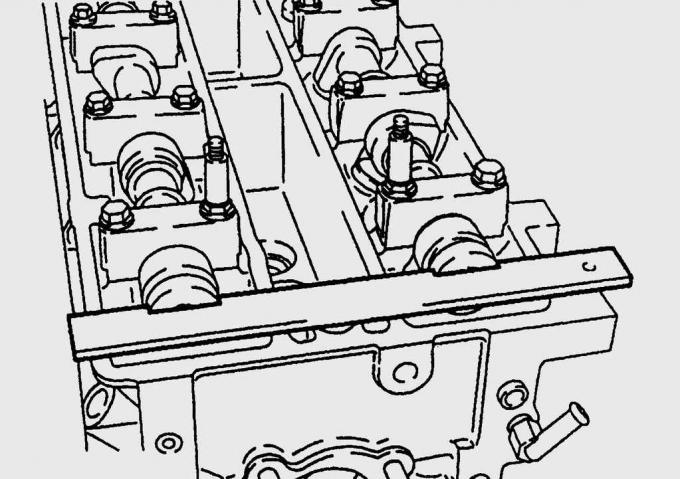

Pic. 4.12. Using a Template (special tool 21-162 for Zetec, 21-162-A for Zetec-SE) for setting the camshafts to the top dead center position of the piston of the first cylinder

Only a special tool will give full confidence in the correct installation of the piston of the first cylinder to the top dead center. Ford technicians set camshafts to top dead center «FROM» using a template (special tool 21-162 Zetec, 21-162-A Zetec-SE) (pic. 4.12).

3. Zetec/Endura-DE engines. Under no circumstances should the crankshaft be rotated when the toothed belt tension is loose - in this case, the belt may imperceptibly jump over the tooth, the valve timing will fail and, as a result, serious engine damage will occur as a result of the impact of the piston bottoms on incompletely closed valves.

PRACTICAL ADVICE

Checking spark plugs

The ignition system is designed to ignite the air-fuel mixture in each cylinder at exactly the right time. In gasoline engines, this is achieved by an electric spark (electrical discharge), created between the electrodes of the spark plug. Previously, spark plugs were very sensitive parts, they had to be changed after 12,000 km of a car's run. Modern materials, lead-free fuels and, above all, the use of high-energy electronic ignition systems have changed the situation dramatically. Although spark plugs are still sensitive to moisture, for example when washing the engine, their service life has increased to 40,000 km. Ford recommends replacing spark plugs after 45,000 km. Therefore, constantly monitor the condition of the spark plugs, check their condition every 20,000 km. By the appearance of the spark plug, a specialist can determine the condition of the engine. Endura engines require a spark plug gap of 1.0mm, and 1.3mm for both Zetec versions.

Visitor comments