Disconnect the gearbox from the engine.

Unscrew evenly, in several stages, the pressure plate mounting bolts. This operation must be carried out very carefully so that the clutch cover does not bend.

Remove the pressure and driven clutch discs.

Check clutch disc for wear. The heads of the rivets must be recessed in the disk by at least 0.5 mm. If at least one of the linings turns out to be oily, it is necessary to identify the place of the leak. If it turns out that oil is leaking from the gearbox, the gearbox input shaft oil seal must be replaced. Also check the condition of the shaft. The working surface of a slightly worn shaft can be wiped with sandpaper with a grit of 240. If there are signs of significant wear on the shaft, it definitely needs to be replaced.

If oil leaks from the flywheel side, remove the flywheel from the shaft and replace the oil seal in the engine rear cover. If the neck of the crankshaft is developed at the point of contact with the edge of the oil seal, it is necessary to remove the shaft and grind its neck.

Check the flywheel for wear. Check for burnt spots on the surface. If there are deep scratches and traces of strong marks on the surface, it is necessary to remove the flywheel and grind its working surface that interacts with the clutch disc. A layer of material no more than 1 mm can be ground. If the surface shows signs of wear and scratches even after grinding, the flywheel will have to be replaced. Install a new or repaired flywheel on the engine crankshaft and fasten with bolts, tightening torques specified in section 1.1.

When replacing the clutch, the release bearing must always be replaced as well.

To install, place the clutch disc on the mounting rod 21-103 or on the old input shaft, seating it in the crankshaft bore. The surface of the clutch disc with the designation "Schwungradseite" ("flywheel") must be in contact with the working surface of the flywheel.

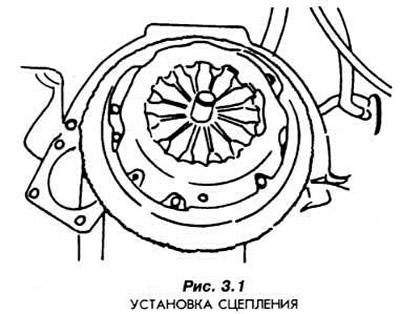

The clutch cover with the pressure plate must be seated on the centering pins located on the edge of the flywheel. Tighten the bolts evenly in several steps (pic. 3.1). At the same time, it is necessary to maintain the value of the bolt tightening torque recommended in section 1.1.

Removing the mounting rod or shaft used to center the disc should not be difficult. Otherwise, loosen the bolts and start centering again.

Visitor comments